Global Injection Moulding Excellence

With decades of expertise in polymer engineering and precision manufacturing, SP Moulding serves as the premier manufacturing partner for OEMs across high-tech industries worldwide. From concept to mass production, we deliver world-class plastic components that power innovation in the most demanding applications.

Engineering Excellence

As a global injection moulding specialist, SP Moulding stands at the forefront of precision manufacturing innovation. For over two decades, we have dedicated ourselves to serving OEMs in the world's most demanding high-tech industries, from aerospace and medical devices to automotive and consumer electronics. Our deep expertise in polymer engineering and advanced manufacturing processes positions us as more than just a supplier, we are a strategic manufacturing partner who works closely with clients on design-for-manufacturing optimization and breakthrough innovation. From initial concept development through full-scale mass production, we deliver world-class plastic components that power the technologies of tomorrow.

Our Mission

Being an innovative, reliable and competitive partner for our customers

Our Vision

Being our customers' preferred supplier of advanced plastic and coating solutions

Excellence in every detail, innovation in every solution.

Søren Ulstrup

SP Moulding CEO

Global Reach, Local Excellence

Serving Industry Leaders Worldwide

With operations spanning multiple continents and partnerships across the globe, SP Moulding delivers world-class injection moulding solutions wherever your business needs us. Our international presence ensures consistent quality, local support, and seamless supply chain integration for OEMs worldwide.

Countries

Continents

Global Clients

Years of Excellence

Innovation & Expertise

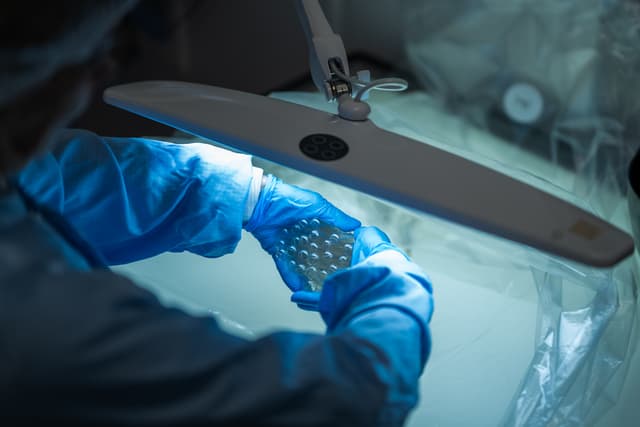

Through continuous investment in process technology and advanced materials, SP Moulding has established itself as the premier engineering partner for OEMs with cutting-edge requirements. Our decades of expertise in polymer engineering and precision manufacturing enable us to collaborate closely with clients on design-for-manufacturing optimization and breakthrough innovation. As your high-tech manufacturing partner, we transform complex concepts into world-class components that meet the most demanding specifications across aerospace, medical, automotive, and electronics industries.

Advanced Manufacturing Technologies

State-of-the-art injection moulding systems and automation platforms deliver unprecedented precision and repeatability for the most complex geometries. Our continuous investment in cutting-edge equipment ensures superior quality and efficiency in high-tech component production.

Polymer Engineering & Material Innovation

Deep expertise in material science drives our selection and optimization of advanced polymer solutions, from high-performance thermoplastics to specialized compounds. Our material experts can help you choose the material you need for your application, for the perfect match of cost and requirements.

Design-for-Manufacturing Collaboration

Our engineers work as an extension of your design team, providing comprehensive DFM consultation from initial concept through production scale-up. This collaborative approach optimizes manufacturability while maintains uncompromising quality standards.

R&D & Process Optimization

Proprietary manufacturing techniques developed through continuous R&D deliver breakthrough solutions for complex moulding challenges. Our process innovation focus ensures optimal cycle times, superior quality, and cost-effective production at scale.

Quality & Compliance Excellence

SP Moulding's unwavering commitment to quality and regulatory compliance sets the gold standard for precision injection moulding across high-tech industries. Our robust quality management systems and strict adherence to global standards ensure that every component meets the exact requirements of OEMs in aerospace, medical devices, automotive, and electronics. As a key differentiator in our industry, our comprehensive compliance framework enables seamless market access while delivering the reliability and traceability that cutting-edge applications demand.

ISO Certified Excellence

ISO 9001, ISO 13485, and ISO 14001 certifications demonstrate our commitment to quality management, medical device standards, and environmental responsibility. Our systematic approach to continuous improvement ensures consistent delivery of world-class components.

Industry-Specific Compliance

IATF 16949 certification for automotive applications and FDA compliance for medical devices ensure we meet the most stringent industry requirements. Our specialized knowledge of sector-specific regulations provides seamless market access across global markets.

Advanced Quality Systems

Comprehensive quality management systems incorporating statistical process control, real-time monitoring, and predictive analytics ensure zero-defect manufacturing. Our robust documentation and traceability systems provide complete audit trails for every component produced.

Continuous Improvement Culture

Rigorous internal audit programs, supplier quality management, and employee training initiatives drive continuous enhancement of our quality processes. Our proactive approach to quality ensures we consistently exceed customer expectations and regulatory requirements.

Strategic Partnerships

At SP Moulding, we don't just manufacture components. We forge strategic partnerships that drive innovation and success. Our collaborative approach transforms us from a traditional supplier into a trusted manufacturing ally that becomes an extension of your team. Through long-term relationships with OEMs worldwide, we deliver comprehensive support from initial design consultation through full-scale production, ensuring your vision becomes reality with uncompromising quality and precision.

Collaborative Engineering Partnership

Our engineering team works as an integrated extension of your design organization, providing comprehensive DFM consultation and technical expertise throughout the entire product development lifecycle. This collaborative approach optimizes manufacturability while ensuring design intent is preserved at scale.

Full Lifecycle Project Management

From concept validation to mass production scale-up, our dedicated project management teams provide seamless coordination and accountability. We take ownership of the manufacturing journey, allowing you to focus on innovation while we handle the complexities of production excellence.

R&D Support & Design Consulting

Leverage our decades of polymer engineering expertise and advanced manufacturing knowledge to accelerate your product development. Our R&D partnership approach includes material optimization, process innovation, and breakthrough manufacturing solutions for your most challenging applications.

Dedicated Account Partnership

Experience the advantages of dedicated account management with deep understanding of your business, technical requirements, and strategic objectives. Our partnership model ensures consistent communication, proactive support, and long-term relationship building that drives mutual success.

Global Manufacturing Network

Our international production footprint delivers unmatched scale and flexibility for OEM partners worldwide. With strategically located facilities across three continents, we ensure supply chain security, local market responsiveness, and seamless global delivery capabilities that power innovation across high-tech industries.

8

Production Facilities

50+

Countries Served

10,000+

Customers

5

Continents Served

Supply Chain Security

Geographically diversified production minimizes risk and ensures uninterrupted delivery to OEM partners worldwide.

Local Market Expertise

Regional teams provide deep market knowledge and cultural understanding to serve local OEM requirements effectively.

Scalable Flexibility

Dynamic production capacity across multiple facilities enables rapid scaling to match changing OEM demand patterns.

Rapid Response Times

Strategic facility placement ensures shorter lead times and faster time-to-market for critical high-tech components.