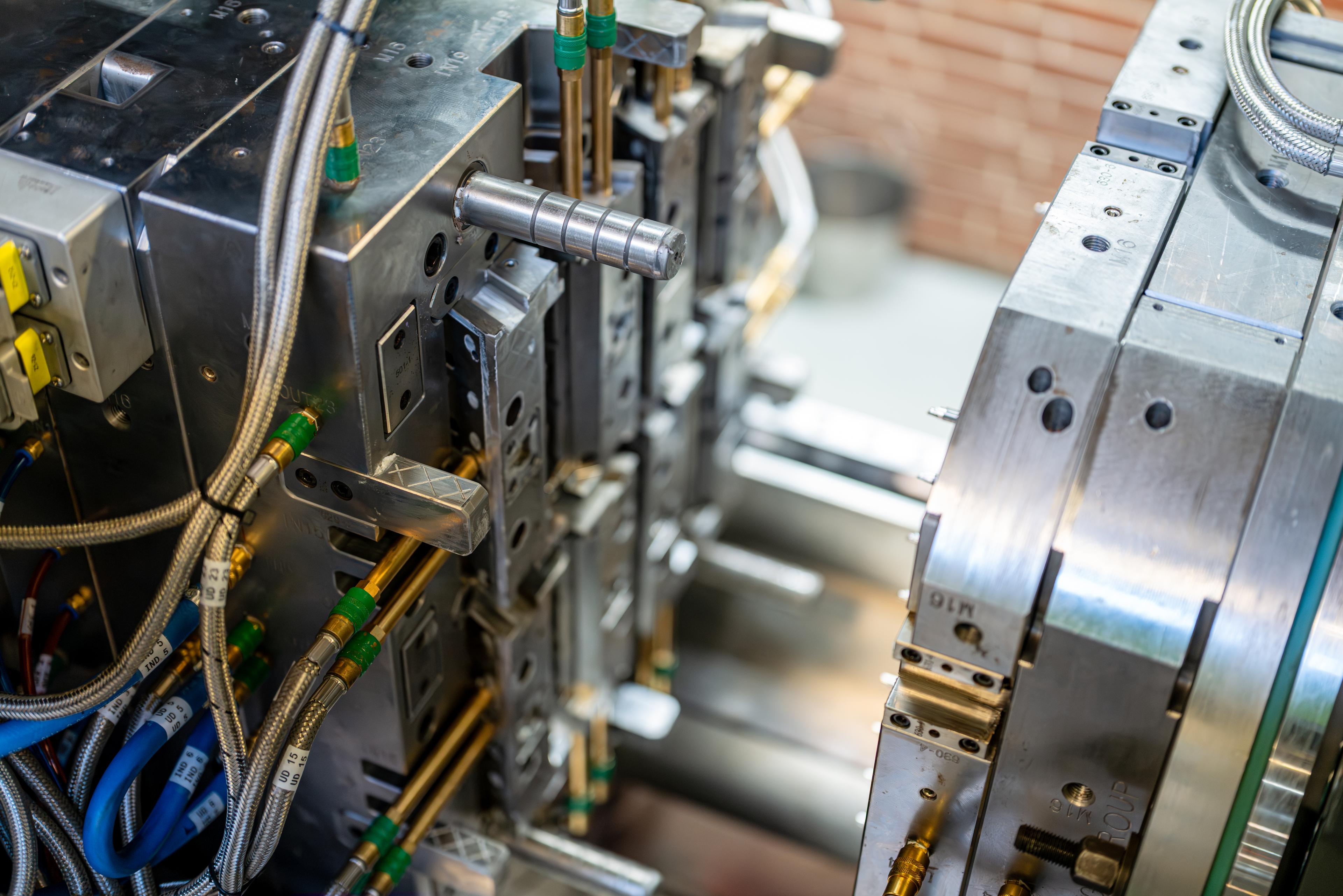

Plastic Injection Moulding Services

Complete manufacturing solutions from prototype to high-volume production. With 500M+ parts annually and global capabilities, we deliver precision plastic components that exceed expectations.

Complete Plastic Manufacturing Solutions

From Concept to Production

As a leading plastic injection moulding specialist, we provide comprehensive manufacturing solutions that span the entire product lifecycle. From initial concept development and prototyping through high-volume production and global distribution, our integrated approach ensures seamless execution and exceptional results. With decades of experience serving diverse industries, we understand the unique challenges of plastic manufacturing and deliver solutions that optimize quality, cost, and time-to-market. Our global network of facilities, combined with advanced technology and skilled expertise, positions us as your ideal manufacturing partner.

Key Highlights

- Complete injection moulding solutions

- Prototype to high-volume production capabilities

- All material types and specialty compounds

- Comprehensive quality control systems

- Global manufacturing and distribution network

- Expert design and engineering support

- Advanced technology and automation

- ISO certified quality management

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

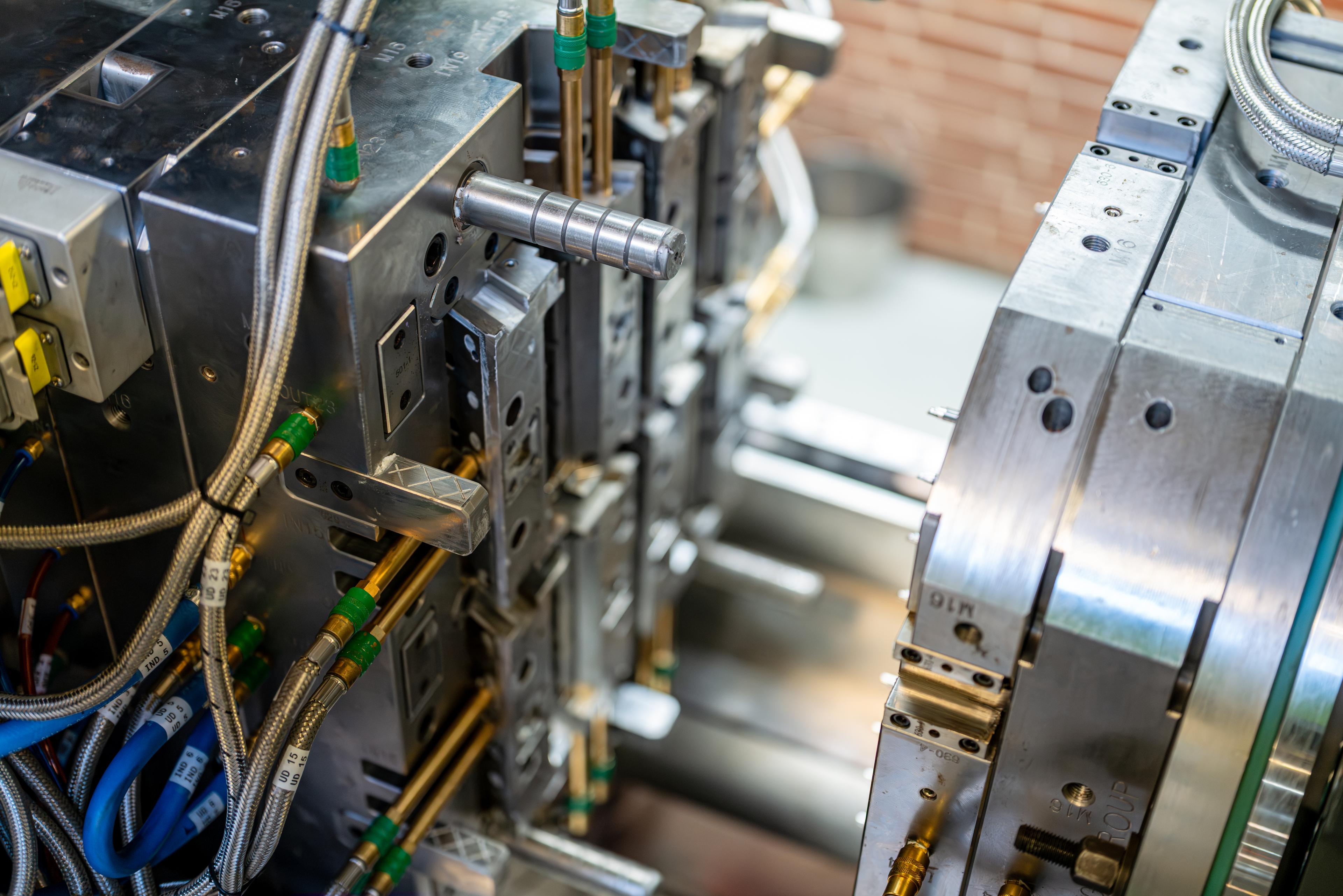

Production Velocity, Precision, and Program Control

Plastic Injection Moulding Advantages

Access a global press fleet, advanced automation, and disciplined quality systems that keep complex injection moulding programs on pace. Our end-to-end ownership compresses launch timelines while maintaining repeatable accuracy, resilient supply chains, and competitive cost structures.

- Global Capacity

- 50-1500 ton presses

Right-size press selection across 8 facilities for prototype, bridge, and mass production volumes.

- Precision Quality

- 99.9% first-pass yield

Digitally enabled SPC, automated inspection, and validation protocols safeguard every lot.

- Material Range

- 500+ resin grades

Commodity, engineering, medical, and high-heat polymers qualified with supplier traceability.

- Advanced Processes

- Insert • 2K • 3K

Multi-shot, insert, and overmoulding solutions integrate electronics, soft-touch, and structural features.

- Automation Ready

- Robotics & MES

Cell automation, end-of-arm tooling, and MES visibility reduce takt time and labor variation.

- Rapid Response

- 24-48h change turn

Cross-functional launch teams manage ECNs, tooling mods, and qualification updates without schedule drift.

Proven Value Creation

Manufacturing Advantages

Our plastic injection moulding programs are engineered to deliver tangible business outcomes—accelerated launches, predictable quality, and resilient supply chains. We combine global capacity, precision tooling, and advanced automation to maximize value through every stage of production.

Integrated Manufacturing Partner

ServiceSingle-source ownership of tooling, validation, production, and logistics to keep programs on schedule.

Key Points:

- Design for Manufacturability workshops

- Prototype and bridge tooling under one roof

- Lifecycle tooling maintenance and refurbish

- Coordinated logistics and fulfillment

Precision Quality Assurance

QualityDigitally enabled quality systems that deliver repeatable parts with full traceability.

Key Points:

- ISO 9001 & 13485 certified workflows

- Real-time SPC with automated alerts

- CMM, vision, and metrology labs in-line

- PPAP, FAI, and validation protocols

Scalable Production Capacity

CapacityFlexible global press fleet that ramps from pilot runs to sustained mass production.

Key Points:

- 50-1500 ton presses across 8 facilities

- Cell design optimized for takt time

- Automation-ready workcells and robotics

- Redundant tooling and disaster recovery

Material & Process Versatility

MaterialsExtensive material library and specialty processes tailored to performance-critical parts.

Key Points:

- 500+ validated thermoplastics and blends

- Insert, overmould, and multi-shot expertise

- Color, texture, and surface finishing options

- High-heat and high-strength engineering resins

Supply Chain Reliability

ReliabilityGlobal footprint and inventory programs that stabilize demand surges and regional disruptions.

Key Points:

- Vendor-managed inventory and Kanban

- Regional manufacturing to cut lead times

- Integrated ERP/MES visibility and reporting

- Dedicated customer success teams

Cost & Lead Time Optimization

EfficiencyContinuous improvement strategies that compress launch timelines and total cost of ownership.

Key Points:

- Cycle time engineering and VA/VE workshops

- Tooling maintenance programs to extend life

- Automated handling to reduce labor content

- Rapid response teams for ECN implementation

Technical Excellence in Production

Manufacturing Capabilities

Our advanced manufacturing capabilities are designed to handle the most demanding applications with precision and reliability.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Machine Range(tons) EquipmentRegularly calibrated | 50-1500 | Comprehensive range of injection moulding machines | |

Shot Capacity(grams) CapacityMaterial dependent | 10-5000 | Wide range of part sizes and weights | |

Annual Capacity(parts) CapacityGlobal facilities | 500M+ | High-volume production capability | |

Tolerance Capability(mm) PrecisionStandard conditions | ±0.05 | Precision manufacturing tolerance | |

Cycle Time(seconds) PerformancePart dependent | 10-300 | Optimized cycle times for efficiency | |

Material Types(grades) MaterialsCertified suppliers | 500+ | Comprehensive material library |