Automotive

Precision automotive components with IATF 16949 certification

Key Applications

IATF 16949 quality management

High-temperature material processing

Safety-critical applications

Automotive supply chain integration

Advanced Applications

IATF 16949 certified quality management system for automotive excellence

Advanced materials processing including high-temperature engineering plastics

Comprehensive testing and validation for safety-critical automotive components

Integrated supply chain solutions supporting just-in-time automotive manufacturing

About Automotive

High-performance injection moulding for automotive applications including interior components, under-hood parts, and safety-critical systems with full IATF 16949 quality management.

Key Features

IATF 16949 certified manufacturing

Automotive-grade material expertise

High-temperature applications

Safety-critical component production

Automotive Injection Moulding Solutions

IATF 16949 Quality Management

Our IATF 16949 certified facility ensures automotive industry quality standards are met throughout the manufacturing process, from initial design through final delivery. This comprehensive quality management system encompasses continuous improvement, customer satisfaction focus, and risk-based thinking throughout all manufacturing operations. Our certification demonstrates our commitment to automotive excellence and enables us to serve Tier 1 and Tier 2 automotive suppliers with confidence.

High-Temperature Materials

Specialized processing of automotive-grade materials including high-temperature plastics for under-hood applications and safety-critical components. Our expertise spans engineering thermoplastics such as PPS, PPA, and PEEK that maintain structural integrity and dimensional stability in extreme automotive environments exceeding 200°C. We ensure proper material selection and processing parameters to meet automotive durability requirements including thermal cycling, chemical exposure, and mechanical stress testing.

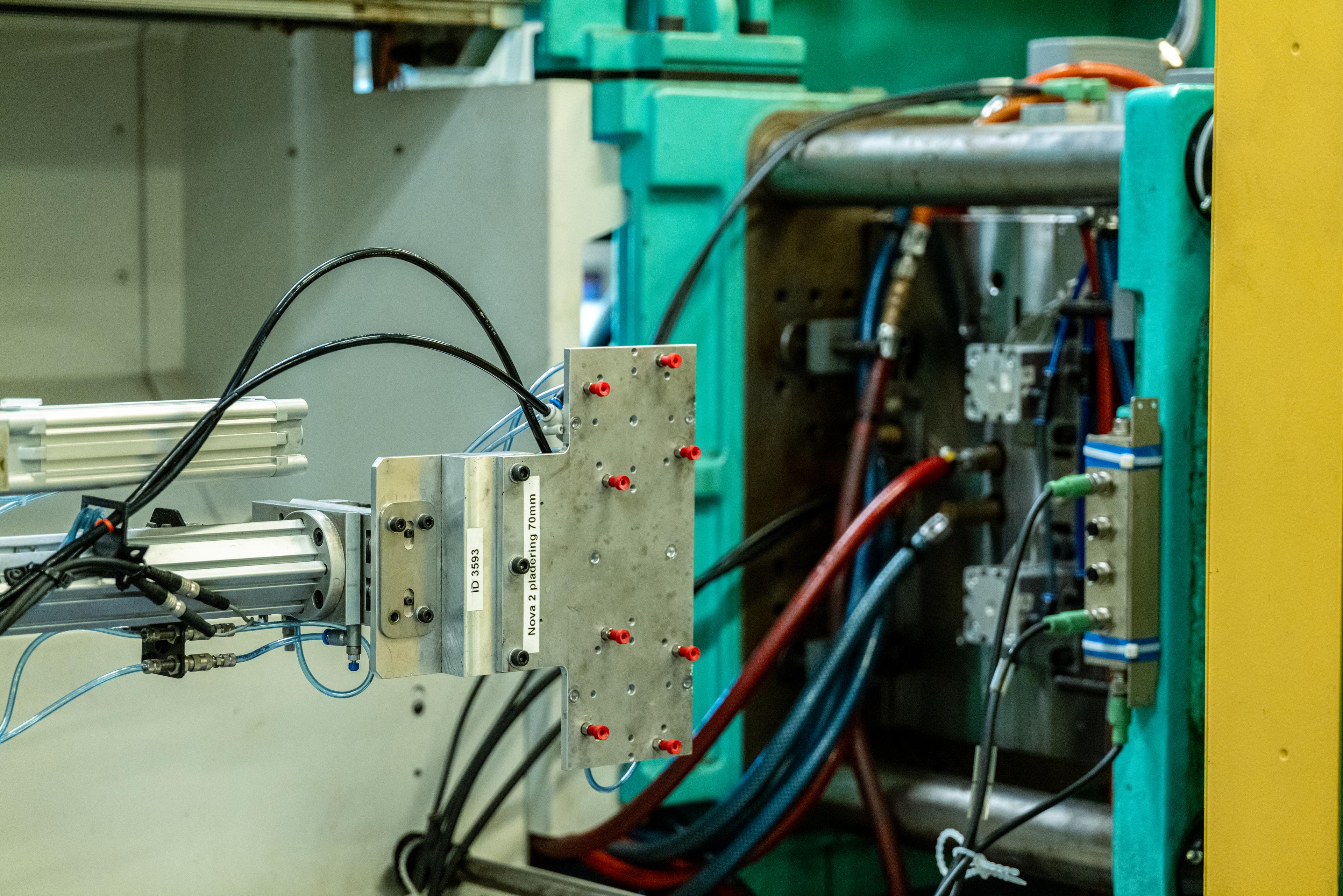

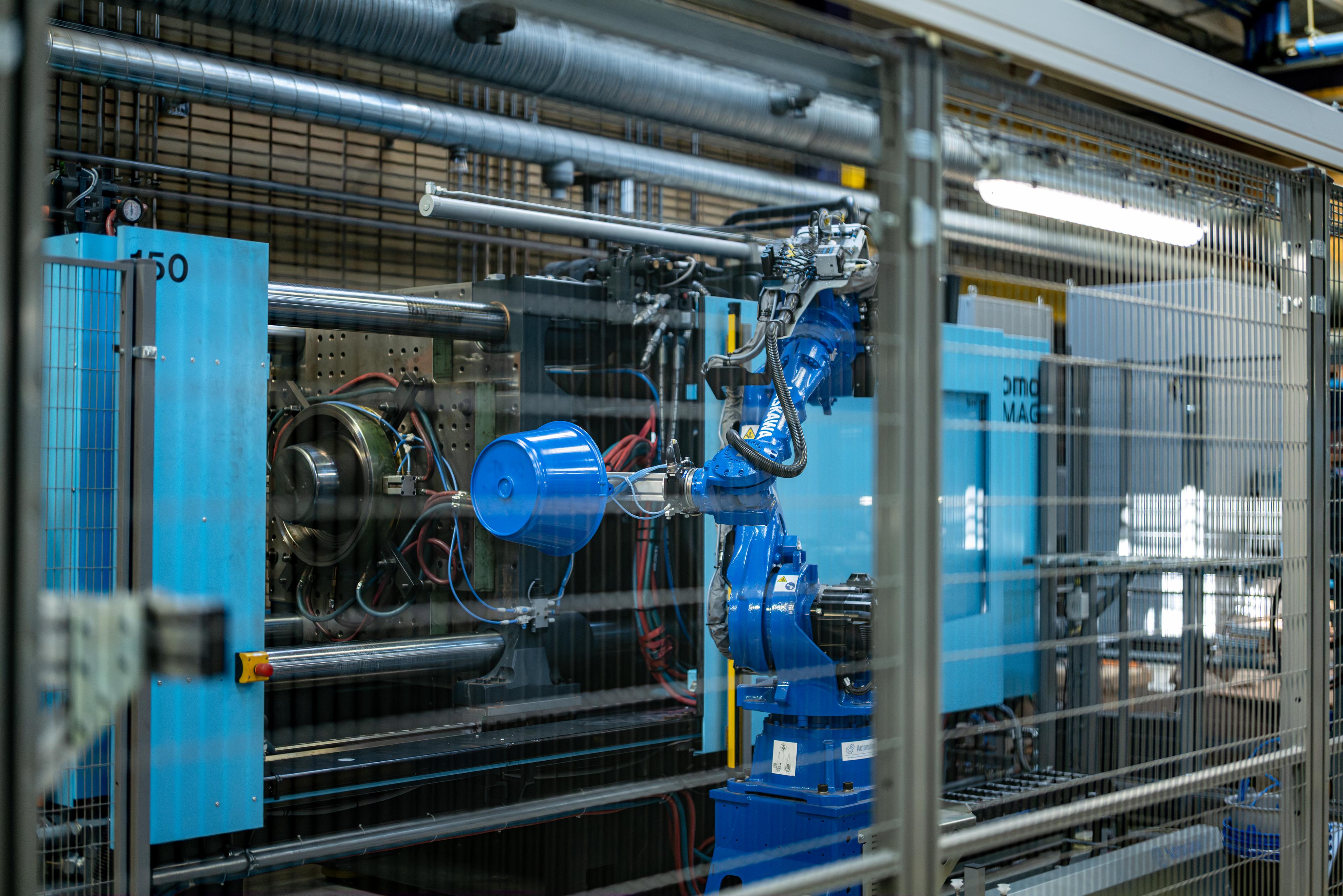

Advanced Tooling & Precision Manufacturing

Our state-of-the-art tooling capabilities include multi-cavity precision moulds designed for high-volume automotive production with exceptional part-to-part consistency. We utilize advanced mould technologies including hot runner systems, gas-assisted injection moulding, and in-mould labeling to optimize cycle times and part quality. Our precision manufacturing processes maintain tolerances as tight as ±0.025mm while ensuring robust production suitable for automotive volume requirements. Temperature-controlled moulding environments and real-time process monitoring ensure dimensional stability across all production runs.

Automotive Testing & Validation Protocols (PPAP, APQP)

We follow comprehensive Production Part Approval Process (PPAP) and Advanced Product Quality Planning (APQP) methodologies to ensure seamless automotive program launches. Our validation protocols include dimensional inspection reports, material certifications, process capability studies, and customer-specific testing requirements. We maintain full statistical process control with Cpk values exceeding automotive requirements and provide complete documentation packages including control plans, FMEA studies, and measurement system analysis. Our quality laboratory performs automotive-specific testing including environmental conditioning, mechanical property verification, and accelerated aging studies.

Supply Chain Integration & Just-in-Time Delivery

Our automotive supply chain integration capabilities support just-in-time manufacturing with EDI connectivity, kanban systems, and synchronized production scheduling. We maintain buffer inventory strategies and rapid response capabilities to support automotive production line requirements with minimal disruption. Our logistics network includes certified packaging solutions, sequenced delivery programs, and real-time shipment tracking to ensure on-time delivery performance exceeding 99.5%. We collaborate closely with automotive OEMs and Tier 1 suppliers to optimize inventory levels while maintaining production flexibility.

Lightweighting & Material Innovation for Fuel Efficiency

We specialize in automotive lightweighting solutions using advanced engineering plastics, glass-filled composites, and carbon fiber reinforced materials that reduce component weight by 30-50% compared to traditional materials. Our material innovation expertise includes selection and processing of bio-based automotive plastics, recycled content materials, and hybrid metal-plastic assemblies that support automotive sustainability goals. We optimize part geometry through advanced simulation and design for manufacturing techniques, enabling thin-wall moulding and structural optimization without compromising mechanical performance or crash safety requirements.

Surface Finishing & Aesthetic Requirements for Interior Components

Our automotive interior component capabilities include premium surface finishing techniques such as in-mould decoration, soft-touch coatings, and grain texturing that meet strict automotive aesthetic standards. We maintain color matching expertise with automotive paint systems and provide Class A surface quality suitable for visible interior applications. Our finishing capabilities include UV-resistant topcoats, antimicrobial treatments, and scratch-resistant surfaces that withstand long-term automotive use. We ensure compliance with automotive interior air quality standards including low VOC emissions and odor requirements through careful material selection and processing control.

Durability Testing for Automotive Environments

Our comprehensive durability testing program validates automotive components under extreme operating conditions including temperature cycling from -40°C to +120°C, humidity exposure, UV radiation, chemical resistance, and vibration testing per automotive standards. We perform accelerated aging studies, thermal shock testing, and fatigue analysis to predict 15-year service life performance in automotive applications. Our testing capabilities include salt spray corrosion testing, impact resistance evaluation, and dimensional stability assessment under thermal cycling. All testing protocols follow ASTM and automotive OEM specifications with full traceability and statistical analysis of results.

Solutions for Automotive

Discover our specialized capabilities designed specifically for the automotive industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

Overmoulding & Insert Moulding

Advanced multi-material moulding techniques for integrated assemblies and enhanced functionality

2K Injection Moulding

Two-component moulding for complex multi-material parts with enhanced functionality