Aerospace & Defense

High-performance components for aerospace and defense applications

Key Applications

Lightweight composite materials

Defense-grade manufacturing

Flame-retardant materials

Advanced Applications

Advanced composite and lightweight material processing capabilities

ITAR compliant manufacturing for defense applications

Specialized flame-retardant and high-temperature resistant materials

About Aerospace & Defense

Precision injection moulding for aerospace and defense industries requiring exceptional strength, lightweight materials, and strict compliance with industry standards.

Key Features

High-performance materials

Lightweight engineering

Critical tolerance capabilities

Aerospace & Defense Injection Moulding

Advanced Materials

Processing of high-performance materials including PEEK, PEI, and carbon fiber composites for aerospace applications requiring exceptional strength-to-weight ratios. Our material expertise extends to specialized aerospace polymers such as PEKK, PPS, and reinforced thermoplastics that maintain structural integrity under extreme operating conditions. We process materials meeting stringent aerospace specifications including flame retardancy, smoke density, and toxic gas emission requirements per FAR 25.853 and other critical aerospace standards.

ITAR Compliance & Security Protocols for Defense Applications

Our ITAR-compliant manufacturing facility maintains strict security protocols and personnel screening procedures required for defense contractor operations. We implement comprehensive export control procedures, secure data handling systems, and restricted access controls to ensure compliance with International Traffic in Arms Regulations. Our facility features segregated manufacturing areas for defense applications with controlled access, security monitoring, and documentation protocols that meet Department of Defense requirements. All personnel involved in defense manufacturing undergo thorough background screening and specialized training in ITAR compliance and security procedures.

Advanced Composite Materials & Lightweight Engineering Solutions

Specialized processing of advanced composite materials including carbon fiber reinforced thermoplastics, glass fiber composites, and hybrid metal-plastic assemblies for aerospace weight reduction initiatives. Our expertise encompasses short and long fiber reinforced compounds, continuous fiber thermoplastic composites, and over-moulded assemblies that achieve weight savings of 40-60% compared to traditional metallic components. We utilize advanced processing techniques including fiber orientation control, consolidation moulding, and hybrid joining technologies to optimize mechanical properties while maintaining aerospace certification requirements. Our engineering team provides comprehensive design optimization services including finite element analysis and structural validation testing.

Flame Retardancy & Smoke Toxicity Requirements (FAR 25.853)

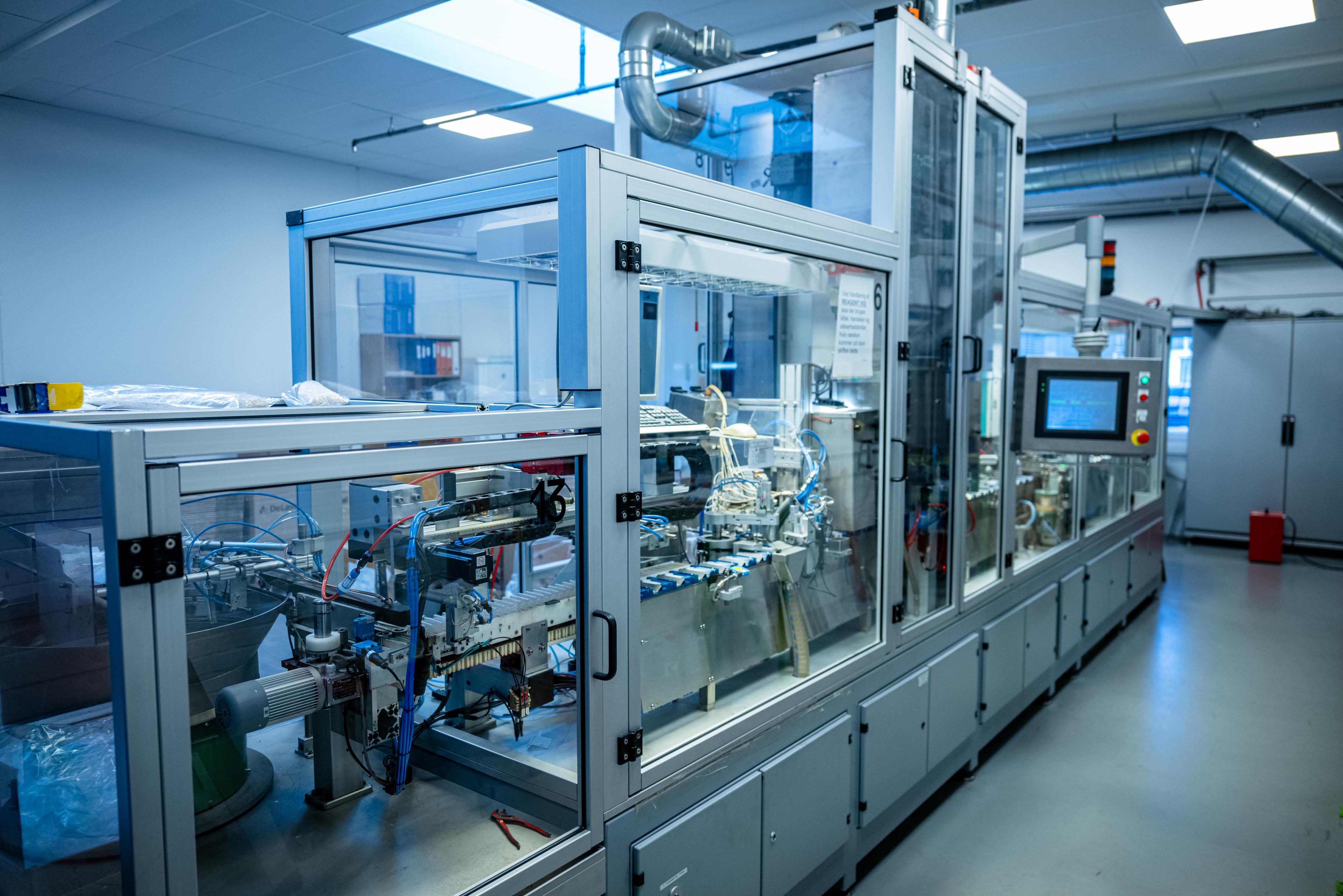

Comprehensive expertise in aerospace flame retardancy requirements including FAR 25.853 compliance for interior aircraft components and related specifications for defense applications. Our materials laboratory maintains specialized testing capabilities for flame spread rate, smoke density measurement, and toxic gas emission analysis using OSU calorimeter and NBS smoke chamber testing protocols. We process inherently flame-retardant polymers and halogen-free flame retardant compounds that meet stringent aerospace requirements for heat release rate, smoke production, and toxic gas emissions. Our quality system includes batch testing and certification protocols ensuring consistent compliance with aerospace flammability standards throughout production runs.

Precision Tooling for Critical Aerospace Tolerances

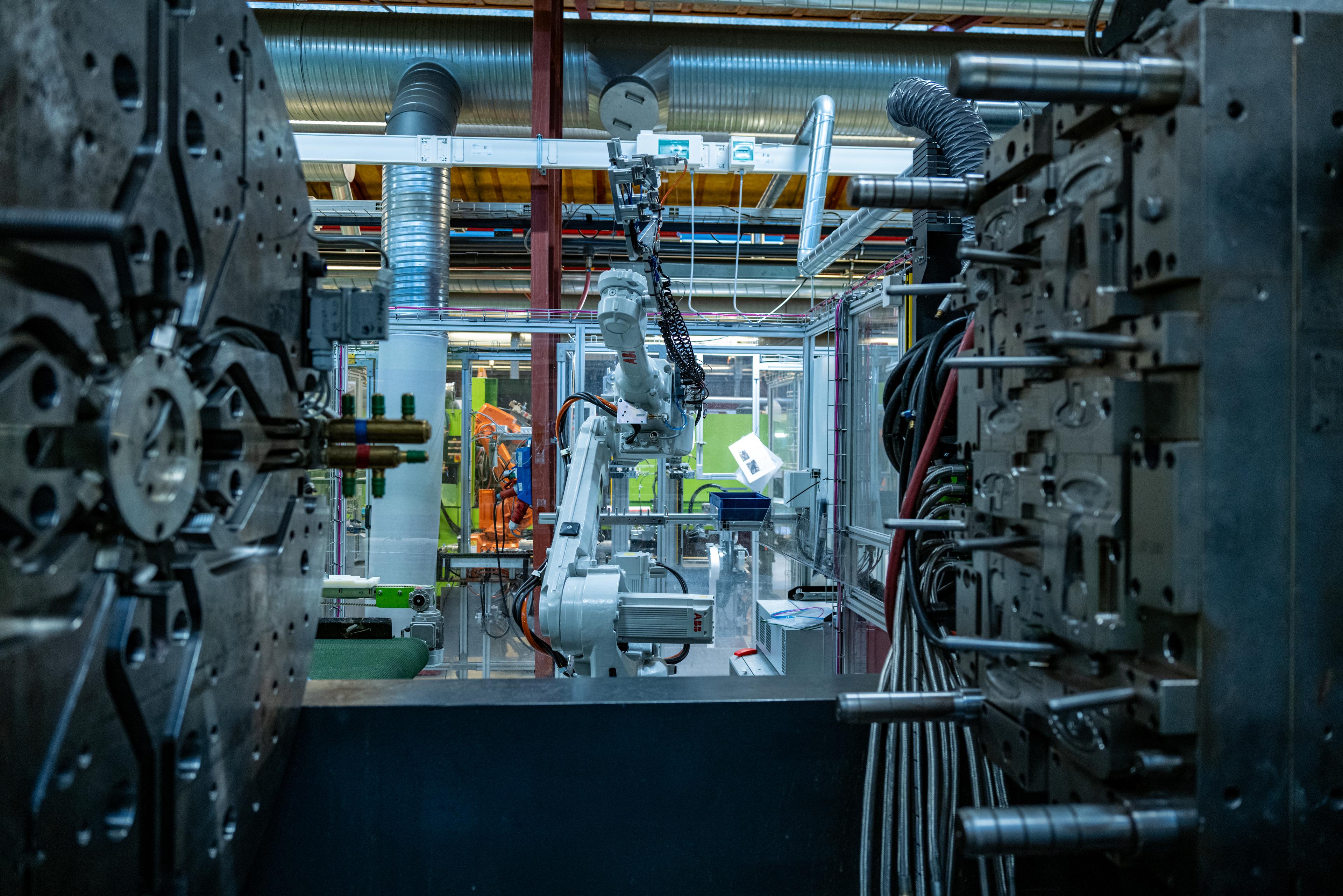

State-of-the-art precision tooling capabilities designed specifically for aerospace applications requiring tolerances as tight as ±0.0005 inches (±0.013mm) with exceptional repeatability across production runs. Our tooling design incorporates advanced cooling systems, precision ejection mechanisms, and in-mould sensing technology to ensure dimensional stability under the demanding processing conditions required for aerospace materials. We maintain comprehensive tool qualification protocols including dimensional verification, process capability studies, and statistical validation of critical dimensions. Our tool maintenance procedures follow aerospace standards with documented calibration, preventive maintenance schedules, and change control processes that ensure continued precision throughout tool lifecycle.

Environmental Testing for Extreme Conditions

Comprehensive environmental testing capabilities validating aerospace components under extreme operating conditions including altitude simulation, thermal cycling from -65°C to +200°C, humidity exposure, salt spray corrosion, and vibration testing per MIL-STD and aerospace specifications. Our testing protocols encompass rapid decompression testing, UV radiation exposure, ozone resistance, and fluid compatibility evaluation with hydraulic fluids, jet fuels, and de-icing compounds. We perform accelerated aging studies and fatigue testing to validate 20+ year service life performance in aerospace environments. All testing follows RTCA/DO-160 environmental standards and customer-specific requirements with complete documentation and statistical analysis of results supporting aerospace certification processes.

Traceability & Documentation Requirements for Aerospace Components

Complete traceability and documentation systems meeting aerospace industry requirements including material certifications, process records, inspection reports, and shipping documentation. Our traceability system maintains comprehensive records from raw material lot numbers through final product delivery with complete genealogy tracking capability. We provide detailed Certificates of Conformance including material test reports, dimensional inspection data, and compliance certifications required for aerospace supply chain integration. Our documentation management system maintains tamper-proof records with electronic signatures, revision control, and long-term archival storage exceeding aerospace retention requirements. We support customer audits and regulatory inspections with immediate access to complete manufacturing history and quality records.

Material Qualification & Certification Processes

Comprehensive material qualification and certification services supporting aerospace applications including material characterization, design allowable development, and regulatory approval processes. Our materials laboratory performs mechanical testing, thermal analysis, chemical resistance evaluation, and long-term environmental exposure studies required for aerospace material specifications. We maintain qualification testing capabilities for tensile strength, flexural properties, impact resistance, fatigue performance, and creep resistance under aerospace operating conditions. Our certification process includes statistical validation of material properties, process capability demonstrations, and preparation of Material and Process Specifications (MPS) supporting aerospace certification programs and customer approvals.

Solutions for Aerospace & Defense

Discover our specialized capabilities designed specifically for the aerospace & defense industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

Metal to Plastic Conversion

Engineering expertise to convert metal parts to high-performance plastics for cost and weight reduction

Quality Assurance

Comprehensive quality control and testing services ensuring the highest standards