Medical Devices

ISO 13485 certified precision moulding for medical devices and surgical instruments

Key Applications

ISO 13485 certified cleanroom facility

Biocompatible material processing

FDA registered manufacturing

Complete regulatory support

Advanced Applications

State-of-the-art Class 8 cleanroom manufacturing environment

Extensive experience with PEEK, PPSU, PEI and USP Class VI materials

Comprehensive design controls and risk management procedures

Full traceability from raw materials to final product delivery

About Medical Devices

Precision injection moulding for life-critical medical devices and surgical instruments. Our ISO 13485 certified cleanroom facilities ensure the highest quality standards for biocompatible components, surgical tools, and implantable devices.

Key Features

ISO 13485 certified cleanroom manufacturing

Biocompatible material expertise

Regulatory compliance support

Precision tolerances for life-critical applications

Medical Device Injection Moulding Excellence

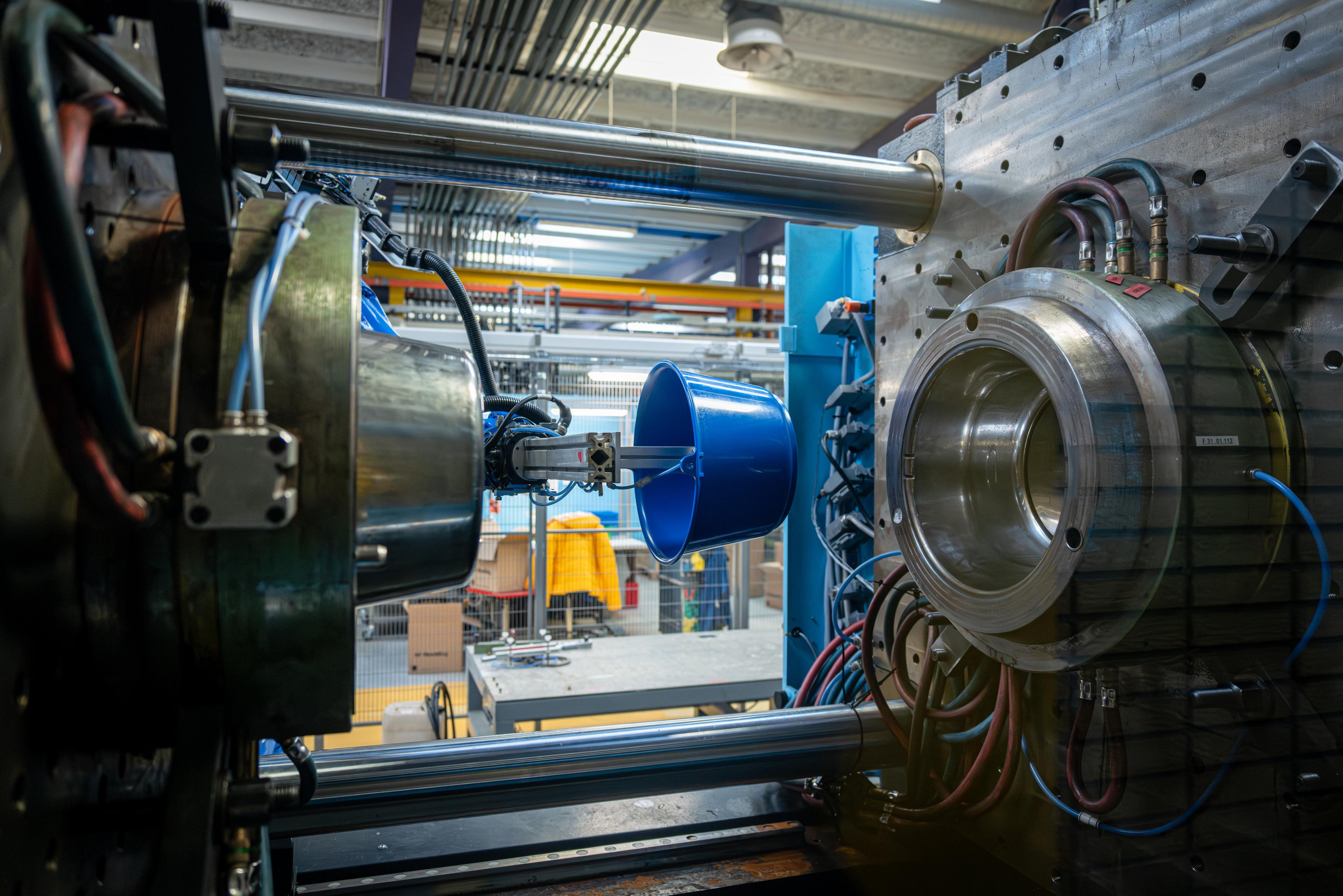

ISO 13485 Cleanroom Manufacturing

Together with our sister company, SP Meditec, our state-of-the-art Class 7 & 8 cleanroom facility represents the pinnacle of controlled manufacturing environments for medical device components. This advanced facility maintains stringent environmental controls including HEPA-filtered air systems, positive pressure differentials, and continuous monitoring of particulate levels, temperature, and humidity.

Biocompatible Material Expertise

SP Moulding's extensive experience with biocompatible materials ensures that every medical device component we manufacture meets the most stringent safety standards for patient contact. Our expertise spans the full range of medical-grade polymers including PEEK, PPSU, PEI, and various USP Class VI certified materials.

Regulatory Support

Navigating the complex regulatory landscape of medical device manufacturing requires comprehensive quality systems and meticulous documentation practices. Our regulatory support services are built on decades of experience with FDA regulations and European MDR requirements.

Quality Control & Validation Processes

Our comprehensive quality control framework incorporates statistical process control, dimensional inspection, and biocompatibility testing protocols specifically designed for medical device manufacturing. Every component undergoes rigorous testing including visual inspection, dimensional verification, and material certification to ensure compliance with ISO 13485 standards. Our validation processes include installation qualification (IQ), operational qualification (OQ), and performance qualification (PQ) protocols to maintain consistent product quality.

Material Selection for Biocompatibility & Sterilization

Strategic material selection for medical devices requires deep understanding of biocompatibility requirements, sterilization methods, and long-term performance characteristics. Our material scientists work closely with clients to select appropriate polymers that can withstand gamma sterilization, ETO processing, or autoclave cycles while maintaining their mechanical properties and biocompatibility. We provide comprehensive material characterization including cytotoxicity testing, sensitization studies, and implantation testing per ISO 10993 standards.

Design for Manufacturing in Medical Applications

Our design for manufacturability (DFM) approach for medical devices focuses on achieving optimal product performance while ensuring consistent, cost-effective production. We evaluate part geometry, wall thickness variations, gate placement, and ejection systems to minimize stress concentrations and potential failure points. Our engineering team considers sterilization requirements, assembly constraints, and patient safety factors during the design optimization process to ensure successful product launch and regulatory approval.

Process Validation & Documentation Requirements

Medical device manufacturing demands extensive process validation and documentation to meet FDA and international regulatory requirements. Our validation protocols include media fills, process capability studies, and ongoing process monitoring to demonstrate consistent manufacturing performance. We maintain comprehensive batch records, traceability matrices, and change control procedures that satisfy 21 CFR Part 820 requirements and support regulatory submissions including 510(k) and PMA applications.

Equipment Qualification & Maintenance Protocols

Our medical device manufacturing equipment undergoes rigorous qualification protocols including installation, operational, and performance qualification phases. Preventive maintenance schedules are validated to minimize downtime and ensure consistent process parameters throughout the equipment lifecycle. We maintain detailed equipment logs, calibration certificates, and maintenance records that support regulatory compliance and enable rapid response to any quality investigations or customer audits.

Solutions for Medical Devices

Discover our specialized capabilities designed specifically for the medical devices industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

Cleanroom Injection Moulding

Class 7 & 8 cleanroom manufacturing for medical and pharmaceutical applications

Micro Injection Moulding

Precision micro moulding for miniature components and medical devices