Renewable Energy

Components for solar, wind, and energy storage systems

Key Applications

UV and weather resistance

Long-term durability

Sustainable materials

Environmental compliance

Advanced Applications

Superior UV and weather resistance for 25+ year outdoor service life

Materials engineered for extreme temperature cycling and environmental exposure

Sustainable manufacturing using recycled and renewable materials

Complete environmental compliance and carbon footprint reduction

About Renewable Energy

Injection moulding solutions for renewable energy applications including solar panel components, wind turbine parts, and energy storage systems requiring long-term durability.

Key Features

UV-resistant materials

25+ year service life

Weather-resistant designs

Sustainable manufacturing

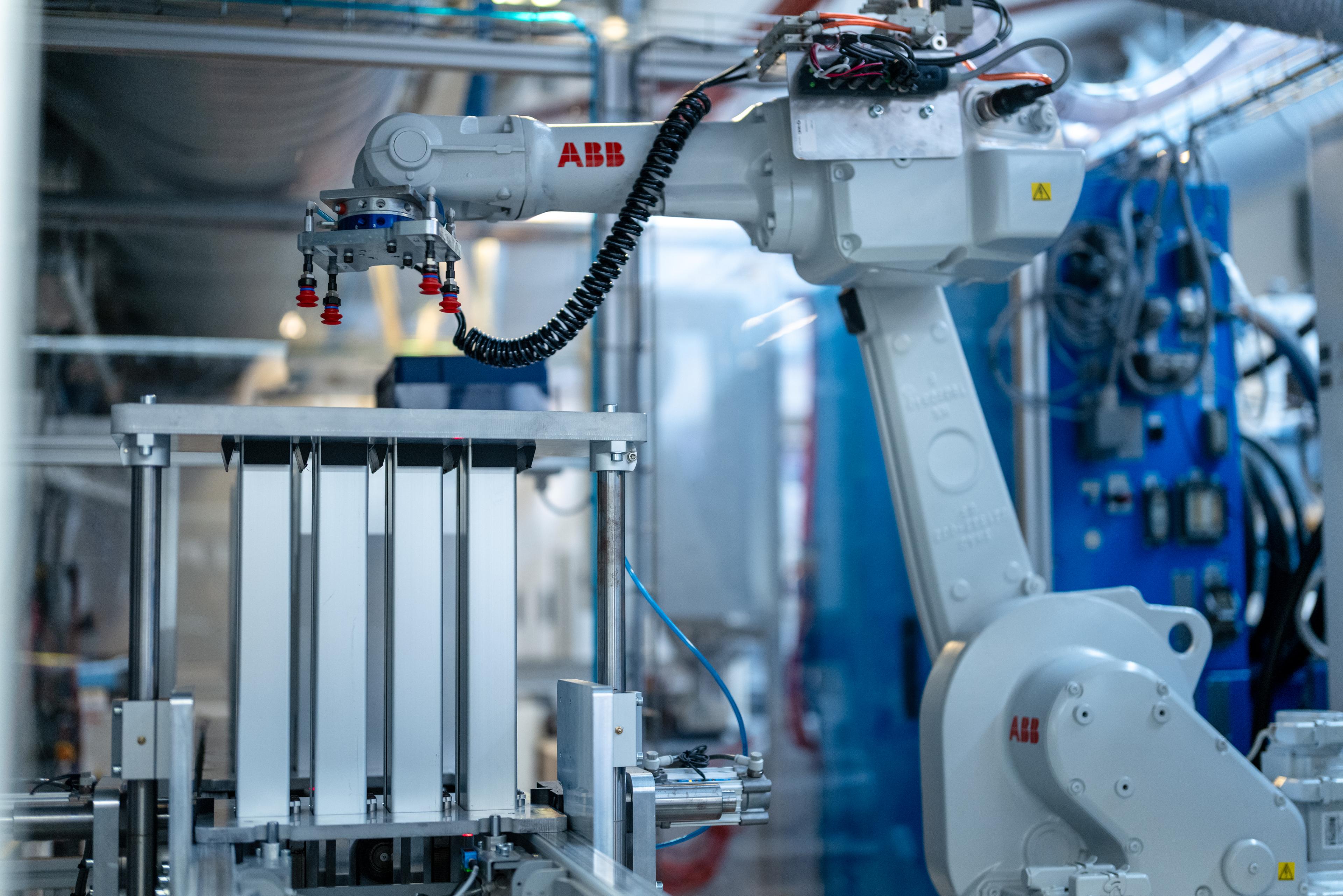

Renewable Energy Injection Moulding

Weather Resistance

Manufacturing components designed to withstand decades of outdoor exposure and extreme weather conditions without degradation. Our weather-resistant materials and processing techniques ensure reliable performance across diverse climatic conditions including hurricane-force winds, hail impact, temperature extremes from -40°C to +85°C, and continuous UV radiation exposure. Advanced polymer stabilization systems protect against photooxidation, thermal degradation, and environmental stress cracking throughout extended service life. We validate weather resistance through accelerated aging protocols including QUV testing, xenon arc exposure, and thermal shock cycling that simulate years of outdoor exposure in compressed timeframes.

Sustainable Production

Implementing sustainable manufacturing practices aligned with renewable energy industry values and environmental goals. Our eco-conscious manufacturing approach incorporates renewable energy sources, closed-loop water systems, and waste minimization protocols that reduce environmental impact while maintaining exceptional quality standards. We utilize bio-based polymers, recycled content materials, and sustainable sourcing practices to support circular economy principles. Our carbon footprint reduction initiatives include energy-efficient processing equipment, optimized logistics networks, and comprehensive lifecycle assessment methodologies that demonstrate measurable environmental benefits throughout the product lifecycle.

Long-term UV Degradation Resistance and Weathering Performance

Advanced UV stabilization and weathering resistance technologies specifically engineered for 25+ year outdoor service life in renewable energy applications. Our comprehensive UV protection systems combine hindered amine light stabilizers (HALS), UV absorbers, and antioxidant packages that provide multi-layer protection against photodegradation and polymer chain scission. Specialized weathering validation protocols include accelerated UV exposure testing per ASTM G154, natural weathering studies at multiple geographic locations, and long-term mechanical property retention analysis. We maintain extensive databases of weathering performance data enabling precise prediction of service life performance and warranty support for solar panel frames, wind turbine components, and energy storage enclosures.

Thermal Cycling Durability for Solar and Wind Applications

Specialized thermal cycling durability engineering for renewable energy components subjected to extreme daily temperature variations and seasonal thermal stress. Our materials expertise encompasses polymers engineered to withstand thermal cycling from -40°C to +85°C with minimal dimensional change, mechanical property degradation, or stress cracking throughout millions of thermal cycles. Advanced thermal analysis capabilities include differential scanning calorimetry (DSC), dynamic mechanical analysis (DMA), and coefficient of thermal expansion (CTE) measurement to optimize material selection and processing parameters. We perform comprehensive thermal cycling validation per IEC 61215 standards for solar applications and IEC 61400 specifications for wind energy systems, ensuring reliable performance throughout 25+ year service warranties.

Electrical Insulation Properties for Energy Systems

Comprehensive electrical insulation capabilities for renewable energy applications requiring superior dielectric properties, arc resistance, and long-term electrical stability. Our materials portfolio includes high-performance electrical insulators with dielectric strength exceeding 30 kV/mm, volume resistivity values above 10^16 ohm-cm, and arc resistance ratings suitable for high-voltage energy conversion systems. We specialize in processing flame-retardant compounds meeting UL94 V-0 specifications and tracking resistance materials per IEC 60112 standards for outdoor electrical applications. Our electrical testing laboratory provides complete electrical property validation including hipot testing, insulation resistance measurement, and comparative tracking index (CTI) evaluation to ensure safe operation in high-voltage renewable energy systems.

Corrosion Resistance for Marine and Offshore Installations

Advanced corrosion resistance engineering for renewable energy components deployed in marine and offshore environments subjected to saltwater exposure, high humidity, and aggressive atmospheric conditions. Our specialized material selection includes inherently corrosion-resistant polymers such as PVDF, ECTFE, and modified polyphenylene oxide compounds that maintain structural integrity under continuous saltwater exposure. We provide comprehensive corrosion testing services including salt spray exposure per ASTM B117, cyclic corrosion testing, and electrochemical impedance spectroscopy to validate long-term performance in marine environments. Our expertise encompasses galvanic corrosion prevention, metal insert protection, and hybrid material assemblies specifically designed for offshore wind installations and marine solar applications.

Dimensional Stability over Extended Service Life

Precision dimensional stability engineering ensuring consistent performance and reliable assembly tolerances throughout 25+ year renewable energy system lifecycles. Our advanced processing techniques minimize residual stress, optimize molecular orientation, and control crystallinity to achieve dimensional stability within ±0.1% over extended temperature ranges and environmental exposure. We utilize specialized annealing protocols, precision cooling systems, and validated processing parameters that eliminate warpage, shrinkage variations, and long-term creep deformation. Comprehensive validation includes long-term dimensional monitoring, accelerated aging studies, and thermal expansion analysis that demonstrates exceptional dimensional stability supporting critical renewable energy assembly requirements and field serviceability throughout system lifetime.

Testing and Validation for 25+ Year Performance Warranties

Comprehensive testing and validation protocols specifically designed to support 25+ year performance warranties for renewable energy applications with statistical confidence and regulatory compliance. Our accelerated testing laboratory utilizes advanced aging protocols including UV/condensation cycling, thermal shock testing, humidity-freeze cycling, and mechanical fatigue testing that correlate with decades of real-world performance. We maintain extensive testing capabilities per IEC 61215, IEC 61730, ASTM D4329, and UL standards providing complete validation packages for solar panel components, wind turbine housings, and energy storage systems. Our statistical analysis methodologies include Weibull reliability analysis, confidence interval calculations, and failure mode assessment that enable accurate service life predictions and warranty support documentation for renewable energy manufacturers.

Sustainable Manufacturing Practices for Green Energy Alignment

Comprehensive sustainable manufacturing ecosystem aligned with renewable energy industry sustainability goals and carbon neutrality objectives. Our green manufacturing initiatives include 100% renewable energy powered production facilities, zero-waste-to-landfill operations, and closed-loop water recycling systems that minimize environmental impact while maintaining world-class quality standards. We implement comprehensive life cycle assessment (LCA) methodologies, carbon footprint measurement, and environmental product declarations (EPD) that demonstrate measurable environmental benefits and support customer sustainability reporting requirements. Our sustainable material sourcing includes bio-based polymer alternatives, post-consumer recycled content integration, and end-of-life recyclability optimization that supports circular economy principles and enables renewable energy manufacturers to achieve their environmental goals throughout the complete product lifecycle.

Solutions for Renewable Energy

Discover our specialized capabilities designed specifically for the renewable energy industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

Metal to Plastic Conversion

Engineering expertise to convert metal parts to high-performance plastics for cost and weight reduction

Quality Assurance

Comprehensive quality control and testing services ensuring the highest standards