Consumer Products

High-quality components for consumer goods and appliances

Key Applications

Premium surface finishes

High-volume production

Consumer safety compliance

Advanced Applications

Superior aesthetic finishes including high-gloss and textured surfaces

Efficient high-volume production for consumer markets

Complete compliance with consumer product safety standards

About Consumer Products

Injection moulding solutions for consumer products requiring attractive aesthetics, durability, and cost-effectiveness across various household and recreational applications.

Key Features

Aesthetic surface finishes

Multi-color capabilities

Cost-effective production

Sustainable materials

Consumer Products Injection Moulding

Aesthetic Excellence

Delivering premium surface finishes and color matching for consumer products that demand visual appeal and tactile quality. Our advanced surface finishing capabilities include Class A automotive-grade surfaces, high-gloss piano finishes, and sophisticated texture reproduction from fine leather grains to bold geometric patterns. We maintain strict quality control over surface defects, ensuring consistent gloss levels, color uniformity, and scratch resistance across high-volume production runs.

Cost Optimization

Efficient manufacturing processes and material selection to meet consumer market price points without compromising quality. Our lean manufacturing principles, optimized cycle times, and strategic material sourcing enable competitive pricing while maintaining consistent quality standards. We implement value engineering approaches that reduce material usage, minimize waste, and optimize part design for efficient production, delivering cost-effective solutions that meet aggressive consumer market pricing requirements.

Multi-Shot and Overmoulding Capabilities for Complex Consumer Products

Advanced multi-shot and overmoulding technologies enabling sophisticated consumer products with integrated soft-touch grips, sealed assemblies, and multi-material constructions. Our specialized two-shot moulding equipment produces complex assemblies in single operations, eliminating secondary assembly processes while ensuring perfect material bonding and dimensional accuracy. We excel at combining rigid structural materials with soft elastomeric surfaces for enhanced user experience, creating products with integrated gaskets, ergonomic grips, and aesthetic color combinations that would be impossible with traditional single-shot moulding processes.

Sustainable Materials and Recycling Programs for Eco-Conscious Consumers

Innovative sustainable material solutions including bio-based polymers, recycled content materials, and closed-loop recycling programs that support environmental responsibility while maintaining performance standards. Our sustainability expertise encompasses post-consumer recycled (PCR) materials, bio-based alternatives, and compostable polymers that meet consumer demands for environmentally responsible products. We provide comprehensive lifecycle assessment support, carbon footprint analysis, and sustainable packaging solutions that help brands achieve their environmental goals while delivering products that meet consumer performance expectations and durability requirements.

High-Volume Production Efficiency and Cost Optimization

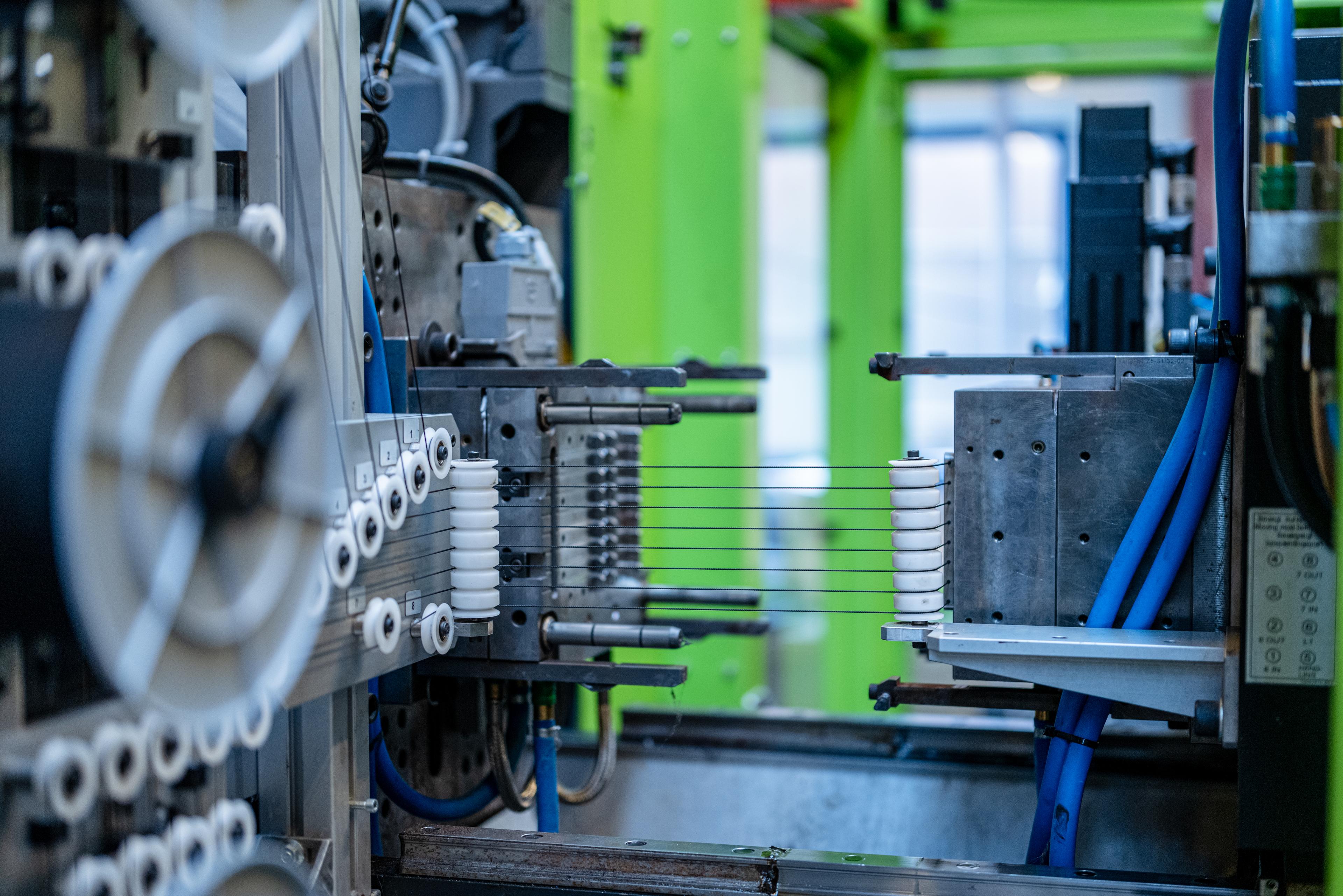

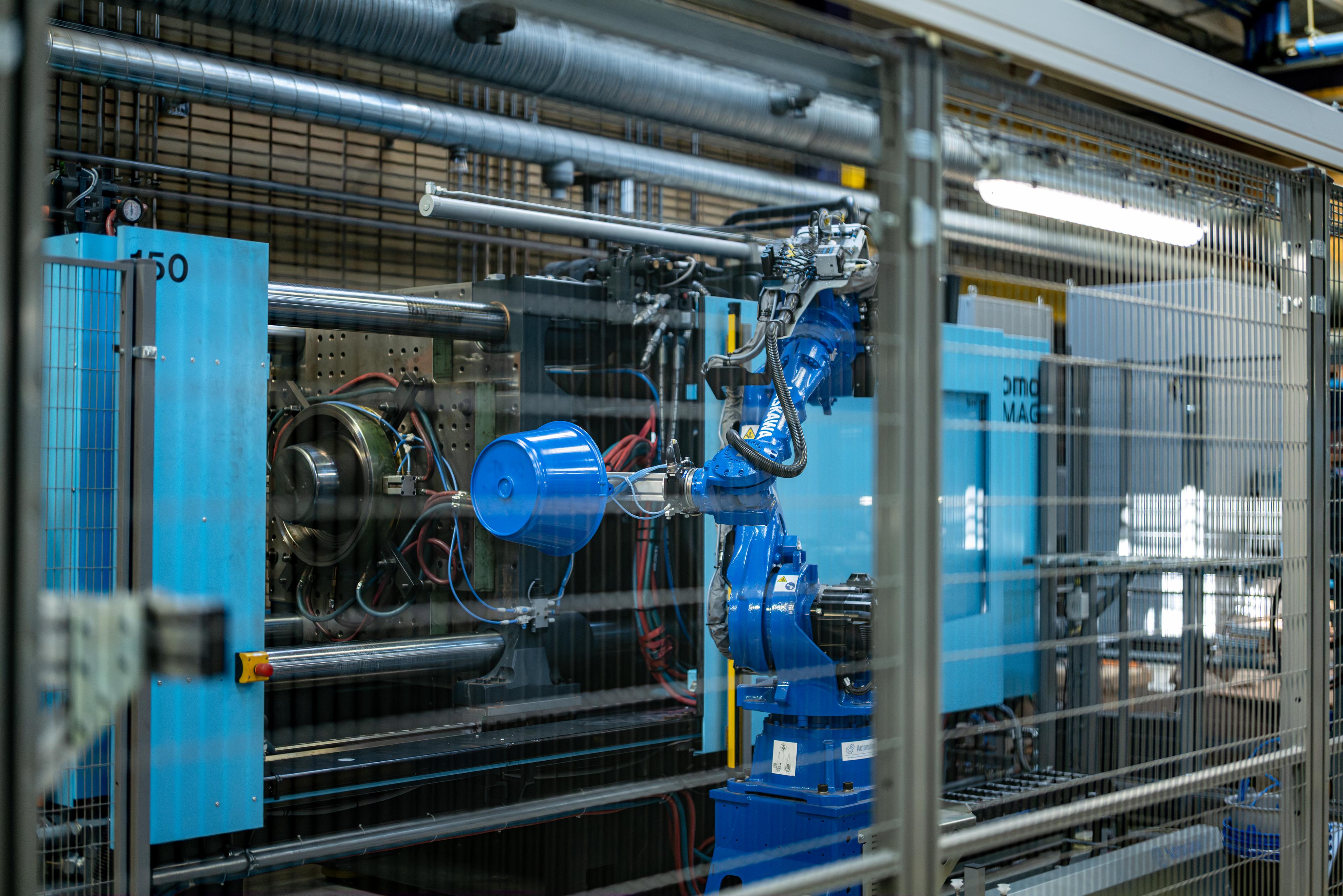

Optimized high-volume production systems capable of producing millions of consumer product components with exceptional efficiency and cost-effectiveness. Our automated manufacturing lines incorporate robotic handling, real-time quality monitoring, and predictive maintenance systems that maximize uptime and minimize production costs. We utilize advanced process optimization techniques including scientific moulding principles, statistical process control, and lean manufacturing methodologies to achieve cycle time reductions of 15-30% while maintaining consistent quality. Our production planning systems enable flexible scheduling and rapid changeovers to support diverse consumer product portfolios and seasonal demand fluctuations.

Surface Texturing and Finishing Options

Comprehensive surface texturing and finishing capabilities ranging from mirror-finish high-gloss surfaces to sophisticated textured finishes including soft-touch, leather grain, and custom branded textures. Our advanced texturing processes utilize precision-etched mould surfaces, chemical etching, laser texturing, and specialized coatings to create distinctive tactile experiences that enhance product appeal and functionality. We offer anti-fingerprint coatings, antimicrobial surface treatments, and scratch-resistant finishes that maintain aesthetic quality throughout extended consumer use. Our finishing expertise includes in-mould decoration, hot stamping, and printing techniques that enable complex graphics and branding directly integrated into moulded components.

Design Optimization for Consumer Appeal and Functionality

Comprehensive design optimization services that balance aesthetic appeal, functional performance, and manufacturing efficiency for consumer products. Our industrial design collaboration includes ergonomic analysis, user interface optimization, and aesthetic refinement that enhances consumer acceptance and market success. We utilize advanced CAD modeling, finite element analysis, and rapid prototyping to validate design concepts before production tooling investment. Our design for manufacturing (DFM) expertise ensures optimal part geometry, wall thickness optimization, and feature integration that supports efficient production while maximizing product functionality and visual appeal in competitive consumer markets.

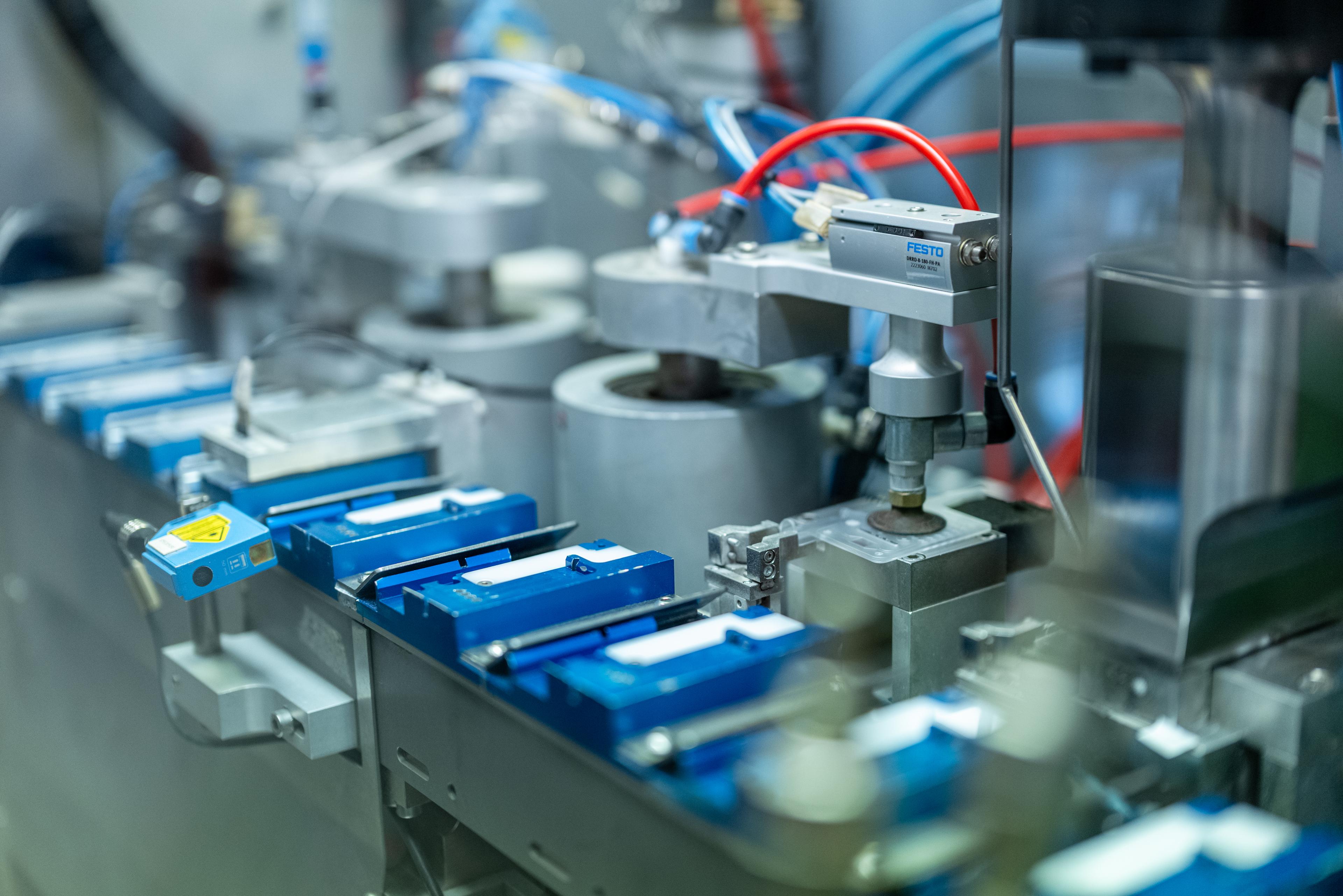

Quality Control for Consumer Safety Standards

Rigorous quality control systems ensuring compliance with consumer product safety standards including CPSC regulations, UL certifications, and international safety requirements. Our comprehensive testing protocols encompass mechanical property validation, impact resistance testing, chemical compatibility evaluation, and aging studies that verify long-term product safety and performance. We maintain specialized testing capabilities for small parts regulations, choking hazard assessment, sharp edge evaluation, and material safety verification including heavy metals testing and phthalate screening. Our quality management systems provide complete traceability and documentation supporting product liability protection and regulatory compliance throughout global consumer markets.

Solutions for Consumer Products

Discover our specialized capabilities designed specifically for the consumer products industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

2K Injection Moulding

Two-component moulding for complex multi-material parts with enhanced functionality

In-Mould Decoration

Advanced decoration techniques applied during the moulding process for superior finish