Electronics

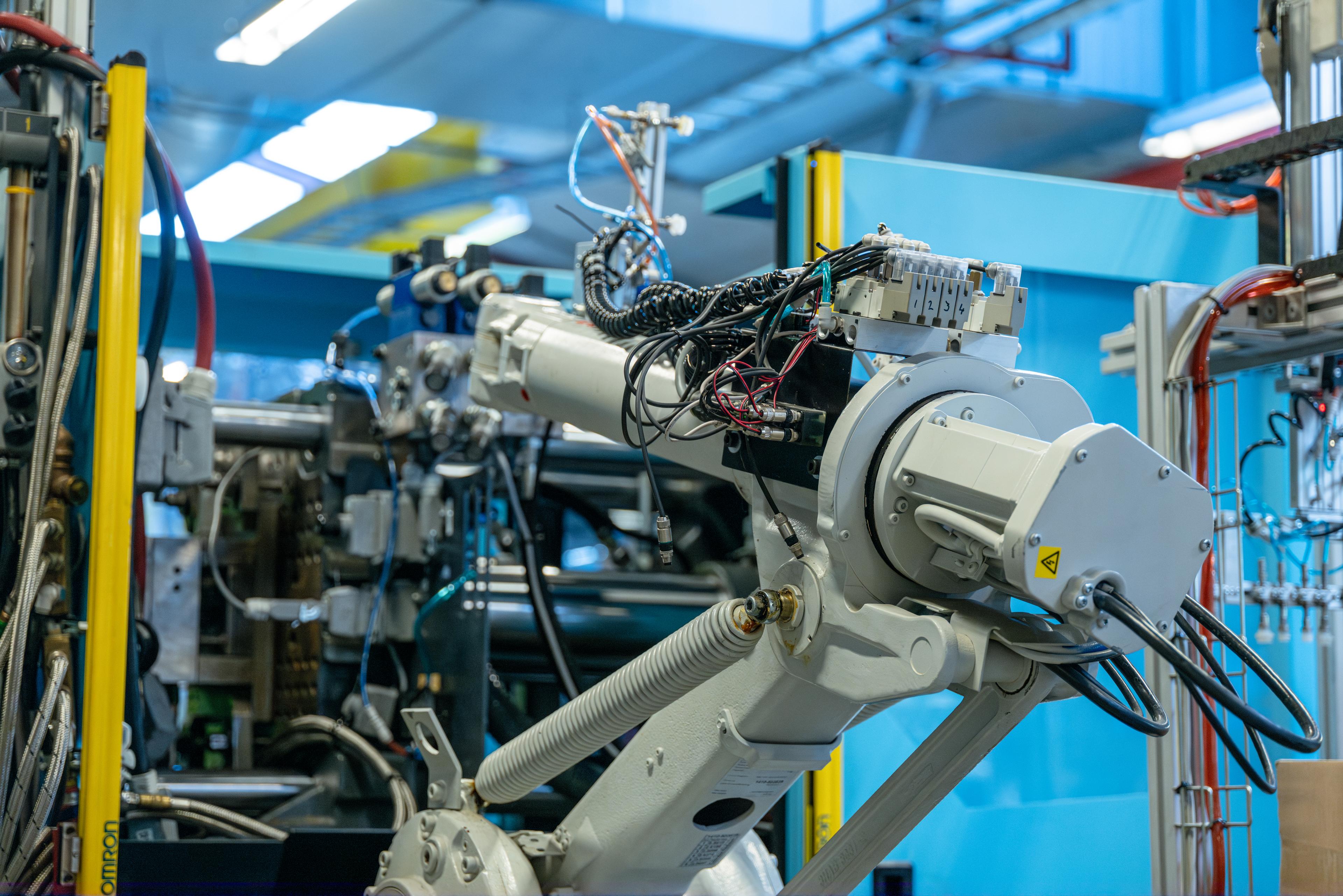

Precision moulding for electronic components and housings

Key Applications

Precision tolerance capabilities

ESD-safe material processing

Micro-moulding applications

Electronic housing solutions

Advanced Applications

Ultra-precise moulding capabilities for electronic components requiring tight tolerances

Specialized ESD-safe materials processing for sensitive electronic applications

Advanced micro-moulding technology for miniaturized electronic components

Complete electronic housing solutions from design to production

About Electronics

Advanced injection moulding solutions for electronic applications including precision housings, connectors, and components with tight tolerances and specialized materials.

Key Features

Precision moulding capabilities

ESD-safe materials

Micro-moulding expertise

Electronic component housings

Electronics Injection Moulding Expertise

Precision Moulding & Tight Tolerances

Advanced precision moulding capabilities enabling tight tolerances down to ±0.01mm required for electronic components and assemblies. Our state-of-the-art injection moulding equipment features servo-driven systems with real-time process monitoring to ensure dimensional consistency across millions of cycles. We specialize in manufacturing intricate electronic housings, connectors, and precision components that demand exceptional repeatability and geometric accuracy. Our quality control systems include coordinate measuring machines (CMM) and automated optical inspection to verify critical dimensions throughout production runs.

ESD-Safe Materials & Conductive Plastics

Processing of ESD-safe materials and specialized engineering plastics designed for electronic applications requiring static dissipation and electromagnetic compatibility. Our expertise includes permanent antistatic compounds, conductive carbon-filled materials, and inherently dissipative polymers that maintain consistent surface resistivity throughout the product lifecycle. We provide materials with surface resistance values ranging from 10^6 to 10^12 ohms per square, ensuring protection of sensitive electronic components during handling and operation while meeting IEC 61340 standards for electrostatic discharge control.

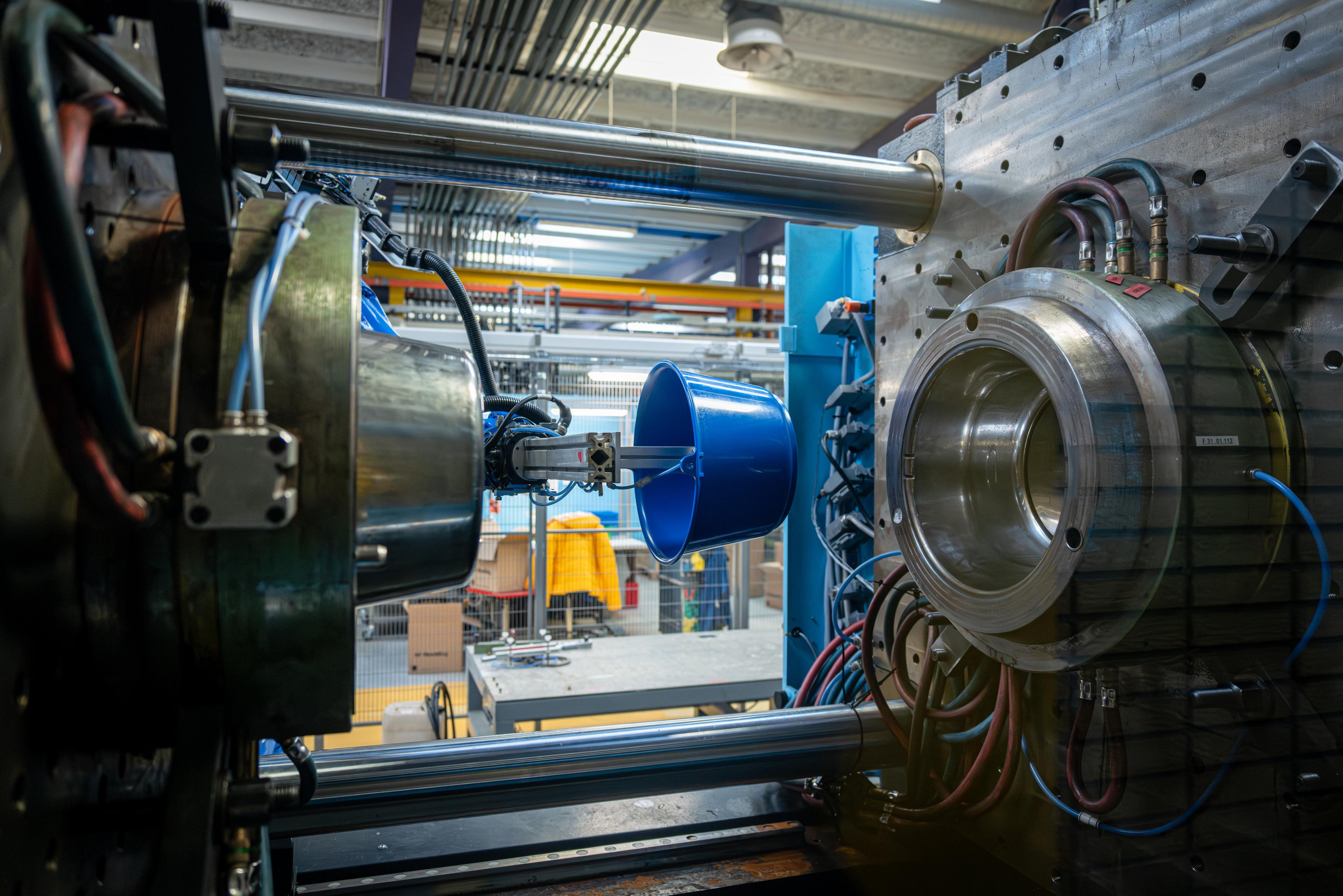

Micro-Moulding & Miniaturization Capabilities

Specialized micro-moulding technology for manufacturing ultra-small electronic components with exceptional precision and surface quality. Our micro-moulding capabilities extend to parts weighing less than 0.1 grams with features as small as 0.1mm, enabling production of miniaturized connectors, sensors, and microelectronic housings. We utilize advanced hot runner systems with precise temperature control and specialized ejection mechanisms to handle delicate micro-components without damage. Our clean manufacturing environment and specialized handling equipment ensure contamination-free production of these precision miniature parts.

EMI/RFI Shielding & Conductive Solutions

Advanced EMI/RFI shielding solutions using conductive plastic compounds and specialized moulding techniques for electronic enclosures requiring electromagnetic interference protection. Our expertise includes processing carbon fiber reinforced composites, metal-filled polymers, and hybrid conductive materials that provide shielding effectiveness exceeding 60dB across critical frequency ranges. We offer both volume conductive materials for consistent shielding and surface conductive coatings applied through in-mould processes. Our testing capabilities include electromagnetic compatibility verification and shielding effectiveness measurement per IEEE 299 standards.

Thermal Management & Heat Dissipation

Specialized thermal management solutions for electronic components requiring efficient heat dissipation and temperature control during operation. Our thermally conductive plastic compounds incorporate ceramic fillers, boron nitride, and aluminum oxide to achieve thermal conductivity values up to 15 W/mK while maintaining electrical insulation properties. We design and manufacture heat sinks, thermal interface components, and cooling channels integrated directly into electronic housings. Our thermal analysis capabilities include finite element modeling and thermal imaging verification to optimize heat transfer performance and prevent component overheating.

Cleanroom Manufacturing for Sensitive Electronics

ISO Class 7 cleanroom manufacturing environment specifically designed for sensitive electronic component production requiring contamination-free processing. Our controlled atmosphere facility maintains strict particulate limits, temperature stability within ±1°C, and relative humidity control to prevent static buildup and contamination. We implement comprehensive contamination control protocols including personnel training, material handling procedures, and environmental monitoring systems. All manufacturing equipment undergoes regular qualification and our cleanroom processes are validated to support production of components for critical electronic applications including medical devices and aerospace systems.

Insert Moulding & Overmoulding for Electronic Assemblies

Advanced insert moulding and overmoulding capabilities for complex electronic assemblies requiring integration of metal contacts, circuits, and electronic components within moulded housings. Our specialized tooling accommodates precise positioning of delicate electronic inserts including PCBs, sensors, and connector pins while maintaining electrical continuity and mechanical integrity. We process low-temperature thermoplastics specifically formulated to prevent thermal damage to sensitive electronic components during the moulding process. Our overmoulding expertise includes soft-touch grips, sealing gaskets, and protective covers that enhance functionality and user experience of electronic devices.

Testing & Quality Control for Electronic Applications

Comprehensive testing and quality control protocols specifically designed for electronic component manufacturing including electrical testing, environmental conditioning, and reliability validation. Our quality laboratory features automated test equipment for measuring surface resistivity, dielectric strength, and electrical continuity of moulded electronic components. We perform accelerated aging studies, thermal cycling tests, and humidity exposure testing to validate long-term performance in electronic applications. All components undergo 100% electrical testing using custom fixtures and our statistical process control systems ensure consistent quality with Cpk values exceeding 1.67 for critical electrical parameters.

Solutions for Electronics

Discover our specialized capabilities designed specifically for the electronics industry.

Plastic Injection Moulding

Complete plastic injection moulding solutions from prototyping to high-volume production

Micro Injection Moulding

Precision micro moulding for miniature components and medical devices

Overmoulding & Insert Moulding

Advanced multi-material moulding techniques for integrated assemblies and enhanced functionality