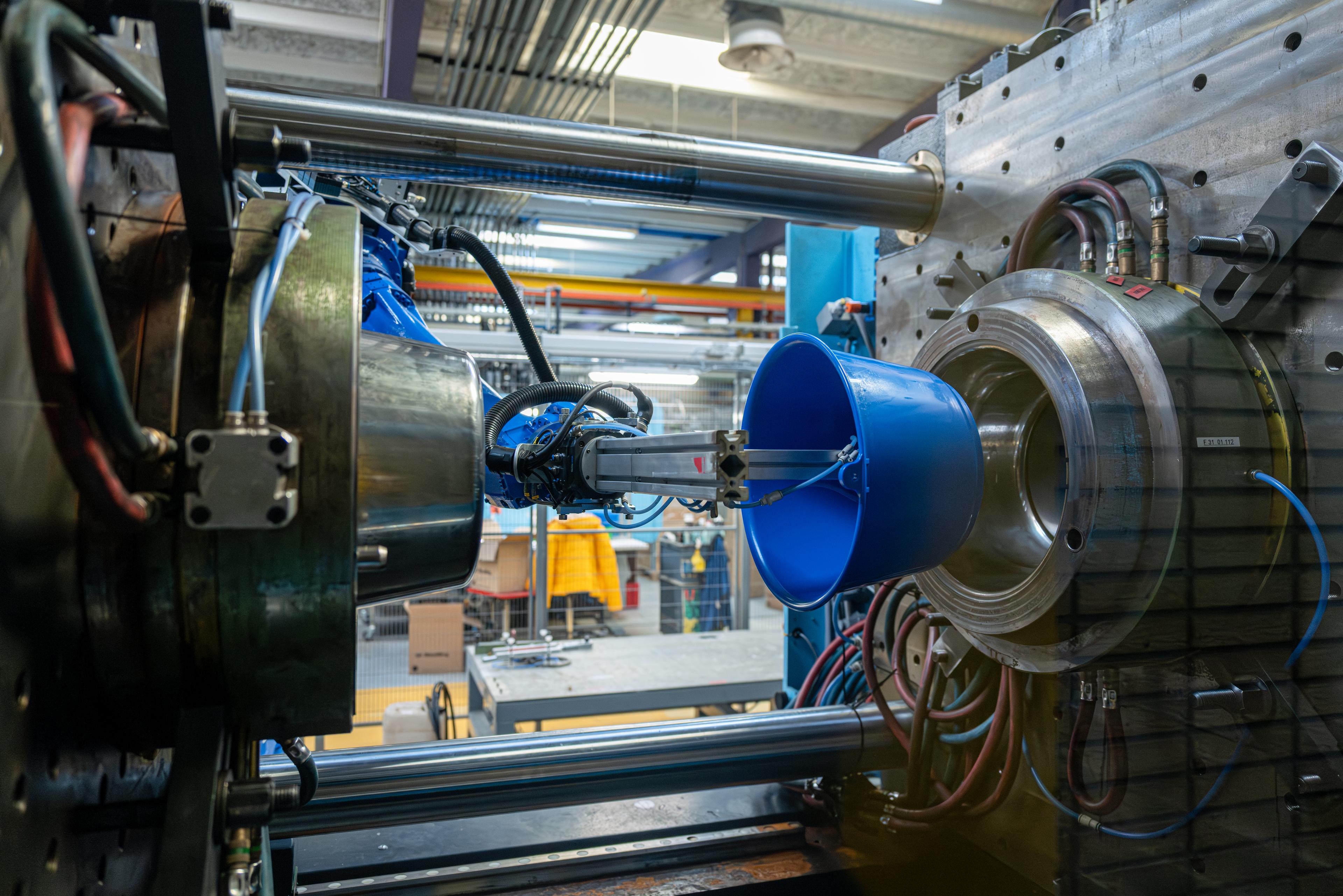

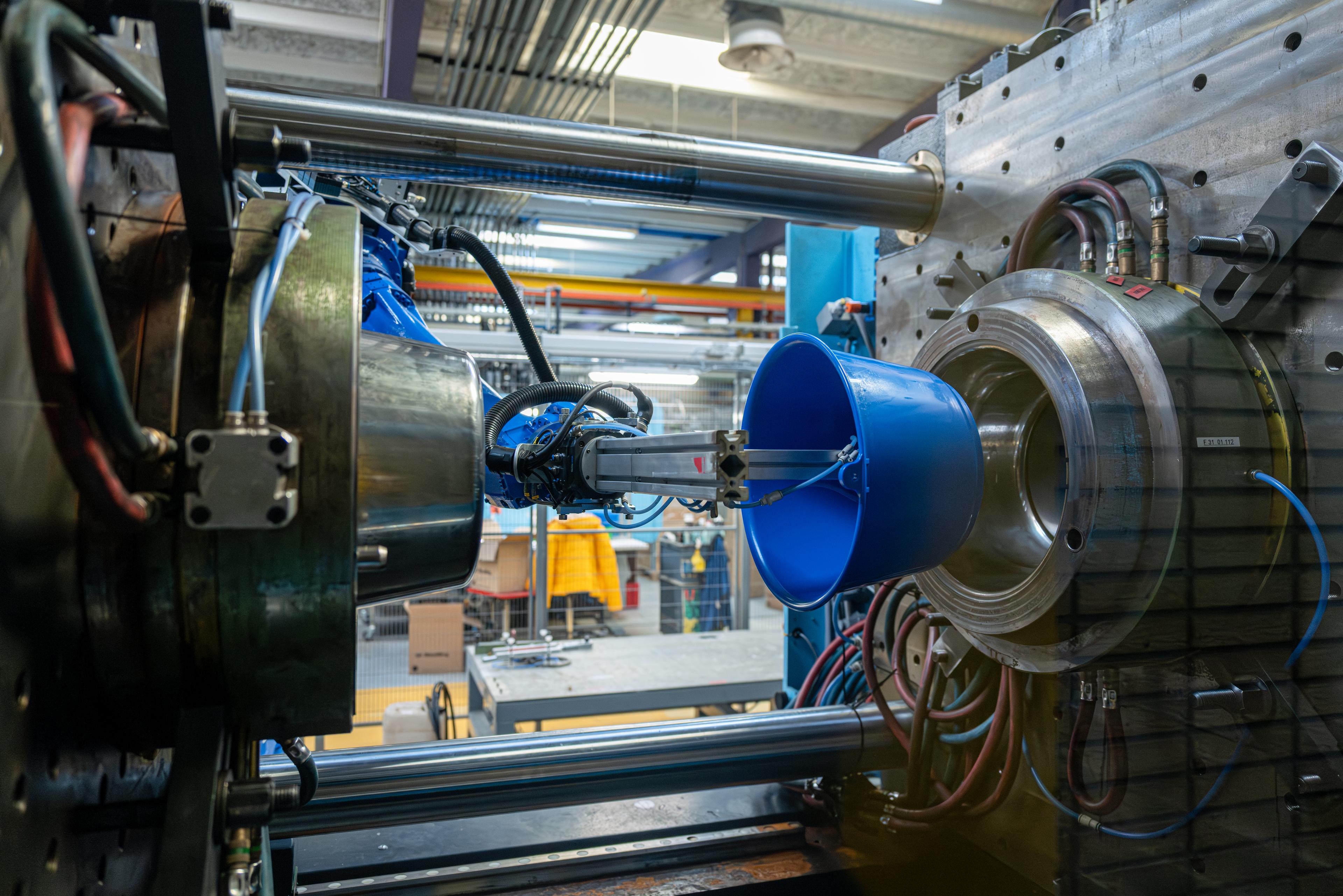

Micro Injection Moulding Excellence

Ultra-precision manufacturing for miniature components. Achieve incredible accuracy with ±0.005mm tolerances and shot weights as low as 0.001g.

Ultra-Precision Micro Manufacturing

Mastering the Art of Miniaturization

Micro injection moulding pushes the boundaries of what's possible in plastic manufacturing. Our specialized equipment, controlled environments, and expert techniques enable the production of components so small they require magnification to inspect, yet with tolerances that rival the best CNC machining. From life-saving medical micro devices to cutting-edge electronic components, we deliver precision at the microscopic scale.

Key Highlights

- Ultra-precision manufacturing capabilities

- Specialized micro moulding equipment

- Controlled cleanroom environment

- Expert micro moulding techniques

- Advanced quality control systems

- Medical device compliance

- Complex micro geometries

- Consistent repeatability at micro scale

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Pushing the Limits of Precision

Micro Moulding Capabilities

Our micro injection moulding capabilities enable the production of components with dimensions and tolerances that were previously impossible with conventional injection moulding.

- Shot Weight Range

- 0.001-5g

Capability to mould extremely small shot weights with exceptional consistency.

- Dimensional Tolerance

- ±0.005mm

Ultra-tight tolerances achievable through specialized equipment and controls.

- Wall Thickness

- 0.05mm min

Ability to mould ultra-thin walls while maintaining structural integrity.

- Feature Resolution

- 10μm

Micro features and details reproducible at the limits of material flow.

Big Benefits in Small Packages

Micro Moulding Advantages

Micro injection moulding offers unique advantages that enable product innovation, cost reduction, and performance improvement across demanding applications.

Miniaturization

Enable product miniaturization while maintaining or improving functionality and performance.

Weight Reduction

Dramatically reduce component weight for aerospace, medical, and portable applications.

Precision Manufacturing

Achieve tolerances and consistency impossible with other manufacturing methods.

Cost Effectiveness

Reduce material usage and enable new product architectures that lower total system costs.

Design Freedom

Create complex micro geometries and features impossible with traditional machining.

High Volume Production

Scale micro component production to millions of units with consistent quality.

Ultra-Precision Technical Capabilities

Micro Moulding Specifications

Our micro injection moulding equipment and processes deliver unprecedented precision and repeatability for the most demanding micro manufacturing applications.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Shot Weight Range(g) Machine | 0.001-5 | Ultra-small to small shot weights | |

Injection Pressure(bar) Machine | Up to 2500 | High pressure capability | |

Clamping Force(tonnes) Machine | 5-50 | Precision clamping | |

Repeatability(CV) Machine | ±0.1% | Shot-to-shot consistency | |

Tolerance(mm) Dimensional | ±0.005 | Ultra-tight dimensional control | |

Wall Thickness(mm min) Dimensional | 0.05 | Ultra-thin wall capability | |

Feature Size(μm min) Dimensional | 10 | Micro feature resolution | |

Surface Finish(μm) Dimensional | Ra 0.1 | Ultra-smooth surfaces | |

Measurement Resolution(μm) Quality | 0.1 | Micro measurement capability | |

Process Monitoring(SPC) Quality | Real-time | Continuous quality control | |

Cleanroom Class(standard) Quality | ISO 14644-7 | Contamination control | |

Documentation(traceability) Quality | Full | Complete quality records |