Quality Commitment

Our dedication to excellence in every aspect of injection moulding manufacturing.

Uncompromising Quality Standards

At SP Moulding, quality isn't just a goal. It's the foundation of everything we do. Our commitment to excellence drives us to exceed industry standards and deliver products that our clients can trust.

From initial design consultation to final product delivery, every step of our manufacturing process is governed by rigorous quality control measures and continuous improvement initiatives.

Our Quality Pillars

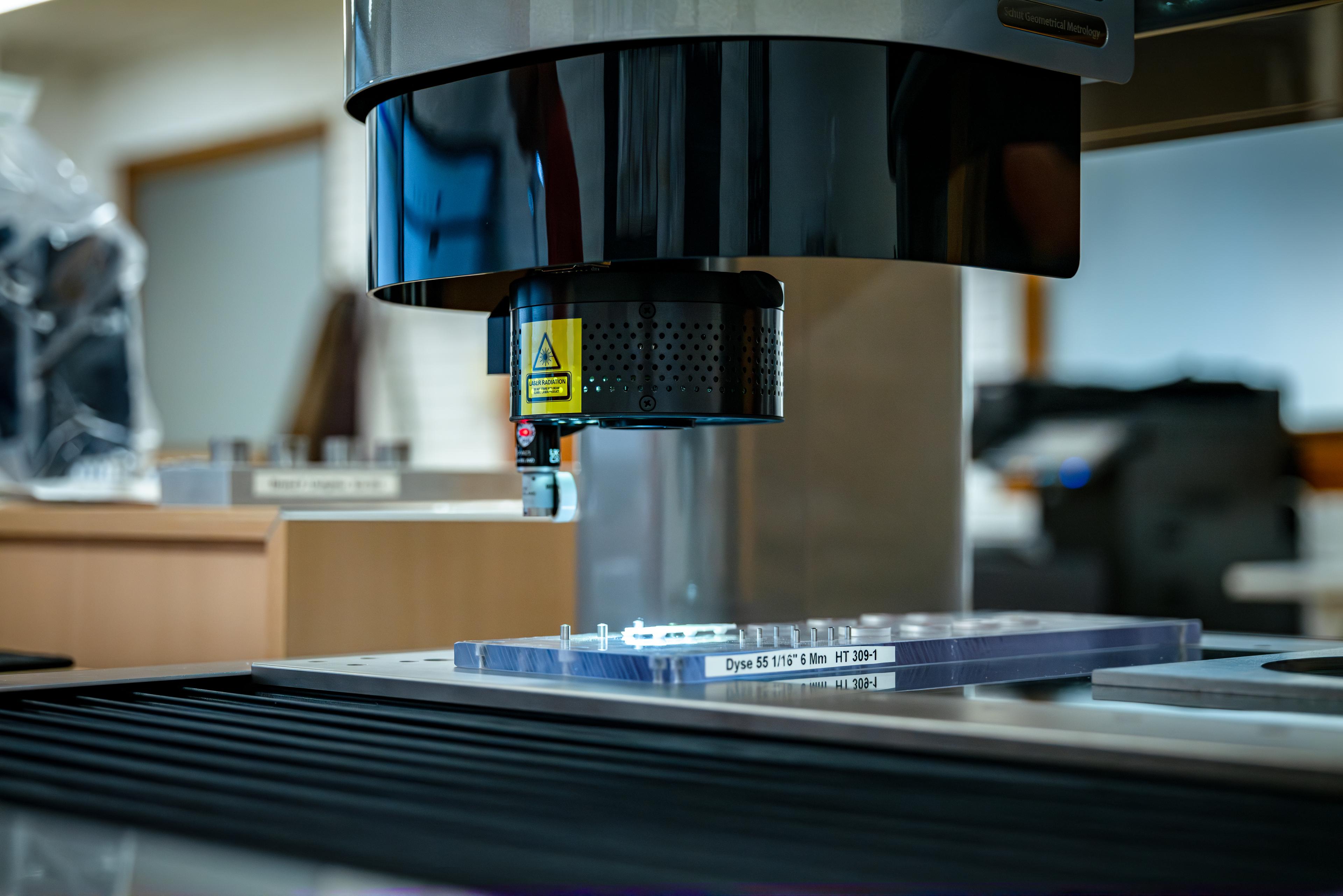

- Precision engineering and manufacturing processes

- Advanced quality control and testing procedures

- Continuous training and skill development

- Customer-focused quality management

Industry Certifications & Standards

ISO 13485

Medical device quality management system certification ensuring the highest standards for medical device manufacturing.

ISO 9001

International standard for quality management systems, demonstrating our commitment to consistent quality delivery.

ISO 14001

Environmental management system standard ensuring responsible environmental practices throughout our manufacturing processes.

IATF 16949

Automotive quality management system standard for automotive production and relevant service parts.

FDA Compliance

Full compliance with FDA regulations for medical device manufacturing and cleanroom operations.

Our Quality Process

Design Review

Comprehensive analysis of design specifications and manufacturability

Process Validation

Rigorous testing and validation of manufacturing processes

In-Process Control

Continuous monitoring and control throughout production

Final Inspection

Comprehensive final quality checks before product delivery