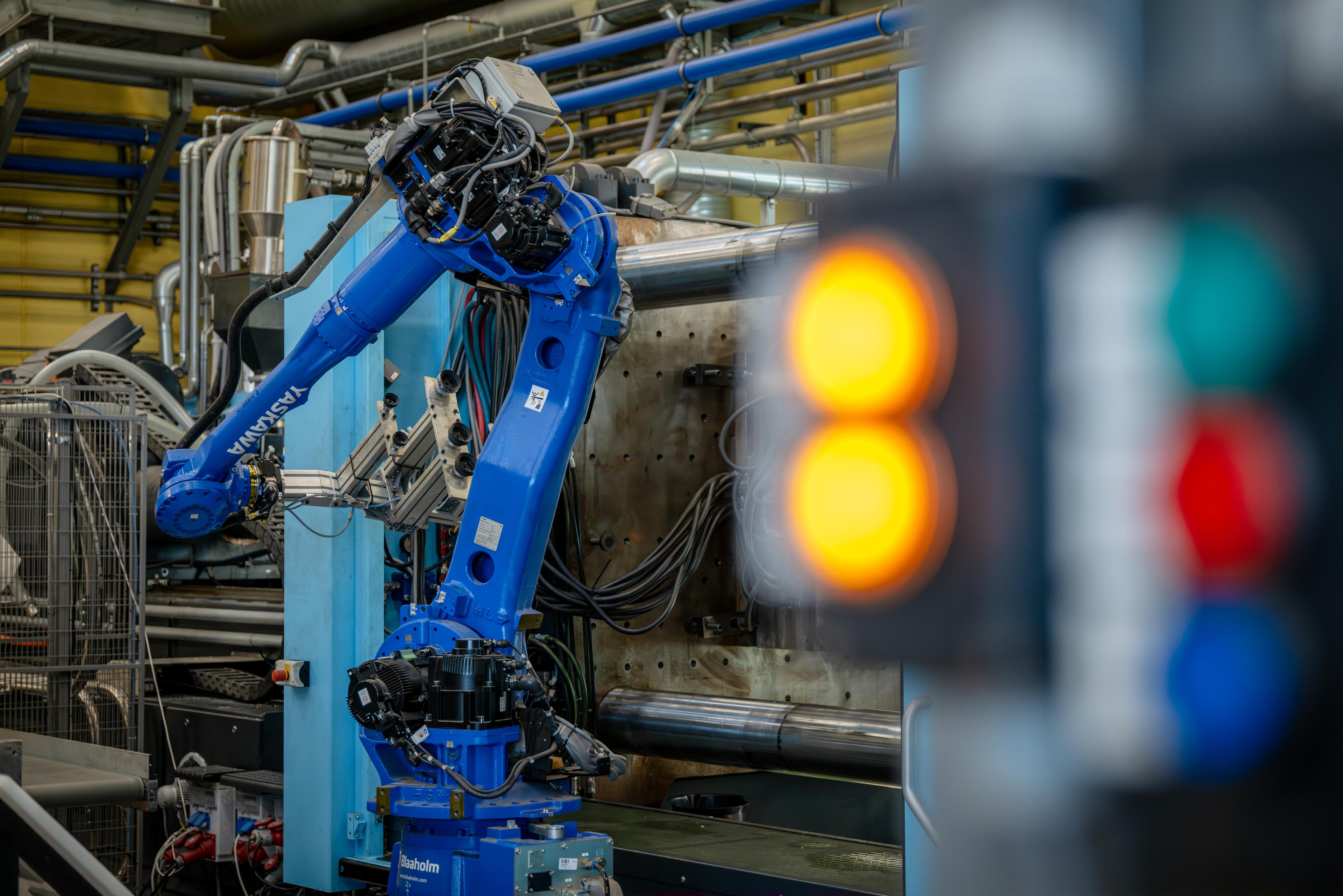

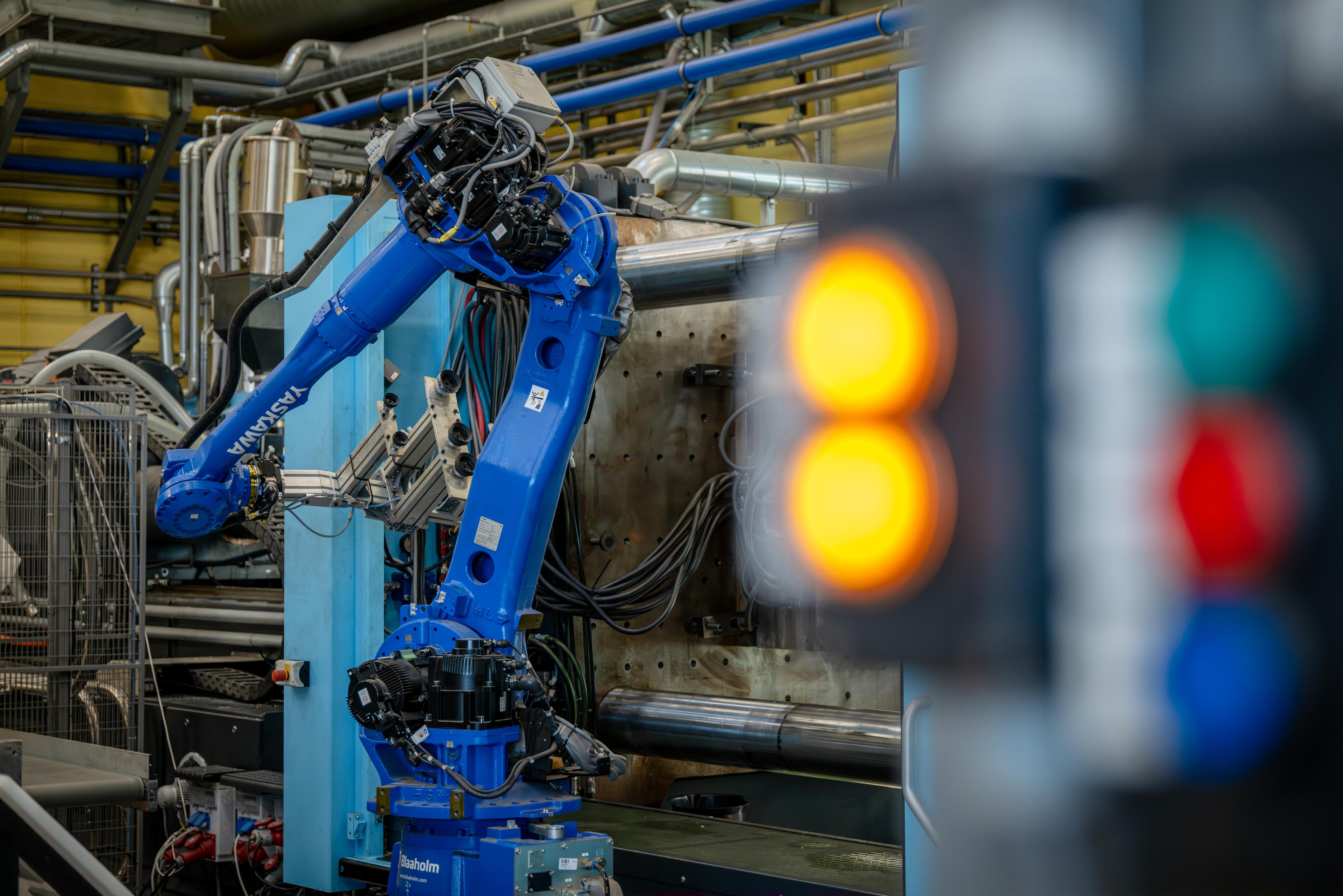

Precision Mould Tooling

World‑class tooling from DFM and simulation to build, qualification, and lifecycle maintenance - engineered for stable processes and long tool life.

Tooling That Drives Production Stability

Design • Build • Validate • Maintain

Our in‑house tooling team designs and manufactures high‑precision moulds optimized for cycle time, part quality, and longevity. We combine DFM, Moldflow simulation, robust steel selection, hot runner expertise, and rigorous qualification to ensure every mould runs repeatably with minimal intervention. Preventive maintenance programs and rapid repair support maximize uptime and total lifetime value.

Key Highlights

- DFM and Moldflow‑guided design

- Precision CNC, EDM, and grinding

- Hot runner and cold runner expertise

- Hardened steels and surface treatments

- Multi‑cavity and family tools

- Scientific sampling and validation

- Spare parts and change kits

- Preventive maintenance and repairs

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Precision, Longevity, Predictability

Tooling Advantages

Our mould tooling delivers stable processes, consistent quality, and lower total cost of ownership through robust design, precise manufacturing, and proactive maintenance.

Dimensional Stability

QualityTight steel tolerances and balanced flow for repeatability

Key Points:

- Optimized gating and cooling

- Precision fit and alignment

- Validated process window

Long Tool Life

ReliabilityHardened steels and preventive maintenance extend tool life

Key Points:

- Material‑appropriate steels

- Surface treatments

- Spare parts strategy

Lower Cost/Part

CostCycle time and scrap reduction through design and qualification

Key Points:

- Efficient cooling layouts

- Balanced runners/gates

- Robust process setup

Fast Ramp

SpeedClear documentation and spares speed up changeovers and ramp‑up

Key Points:

- Setup sheets

- Spare inserts/electrodes

- PPAP/FAI package

Design & Build Parameters

Technical Specifications

Representative specifications for design, manufacturing, and qualification - actual values depend on geometry, material, and production requirements.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Steel Grades Materials | P20, H13, S136, 1.2344 | Tool steels matched to wear, polish, and corrosion needs | |

Tolerance Capability(mm) PrecisionControlled environment | ±0.01 | Typical steel machining tolerance | |

Cavity Count(cavities) Capacity | 1–64 | Single cavity to high‑cavitation tools | |

Runner Systems Process | Hot/Cold | Balanced runners and gate design per part geometry | |

Cooling Process | Conventional/Conformal | Optimized cooling circuits for cycle time and warp control | |

Surface Finish Finish | SPI A–D | Polishing and texturing to spec |