Manufacturing Capabilities

Advanced injection moulding technology and comprehensive manufacturing solutions. From design to delivery, we provide the complete capabilities your project needs.

Our Track Record

Proven Manufacturing Excellence

Industry-leading capabilities backed by decades of experience and continuous innovation.

75+ Years

Manufacturing Experience

Decades of expertise in plastic injection moulding

100B+

Parts Produced

Proven track record of high-volume production

600+ Materials

Certified Resins

Extensive material selection for any application

Class 7 & 8

Cleanroom Facility

Medical device manufacturing environment

All Capabilities

Complete Range of Manufacturing Services

Explore our comprehensive capabilities across all categories, from advanced injection moulding to specialized materials and value-added services.

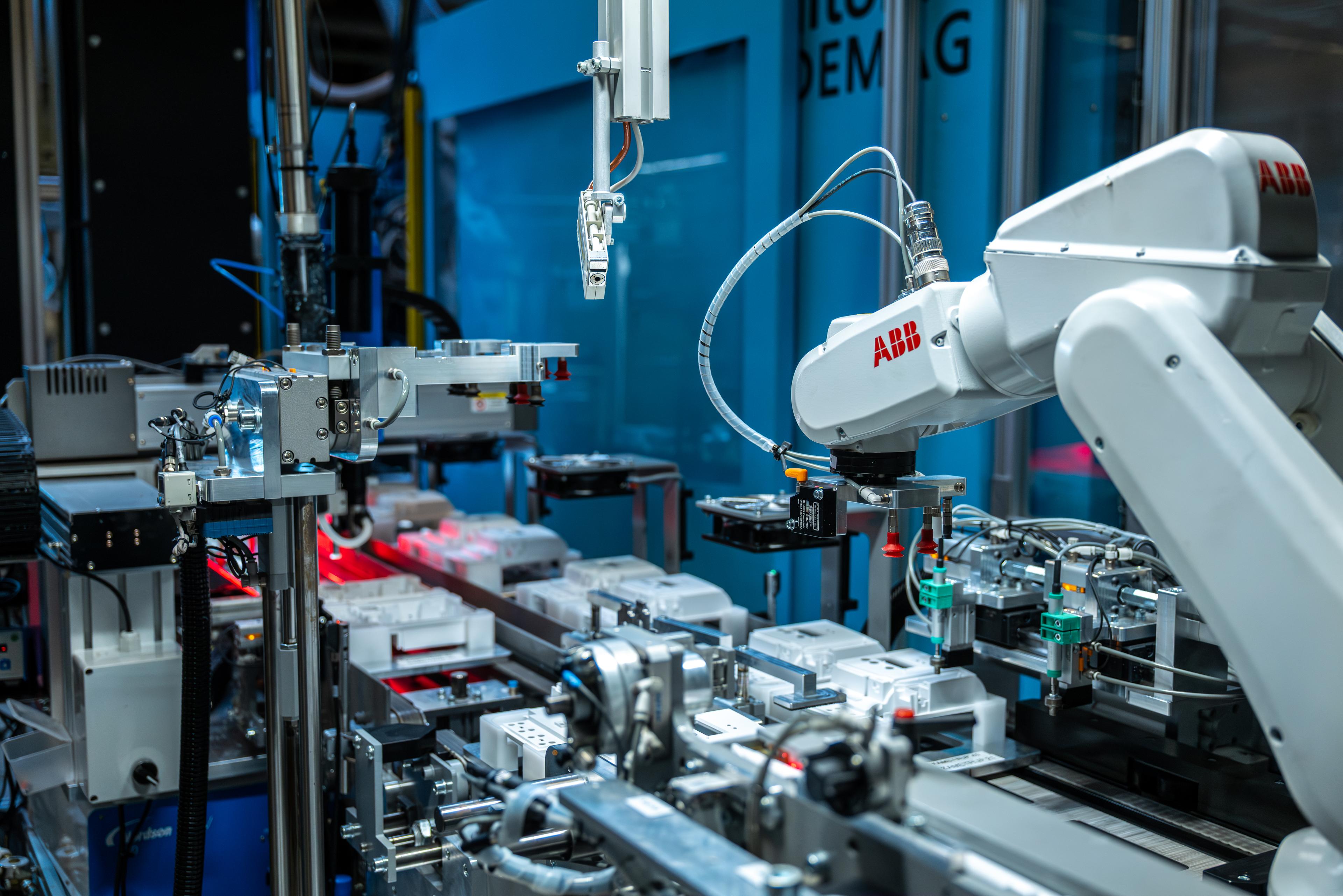

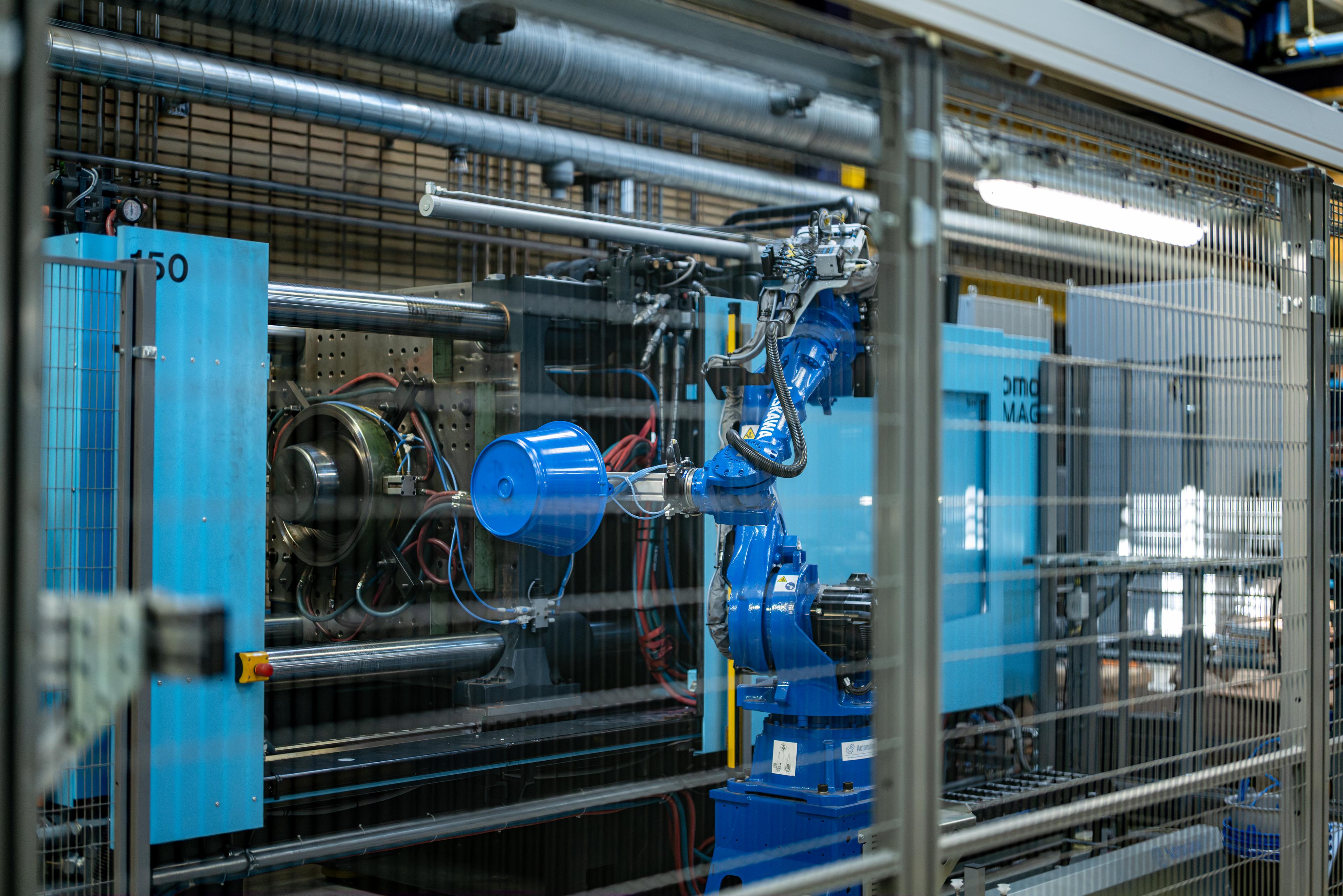

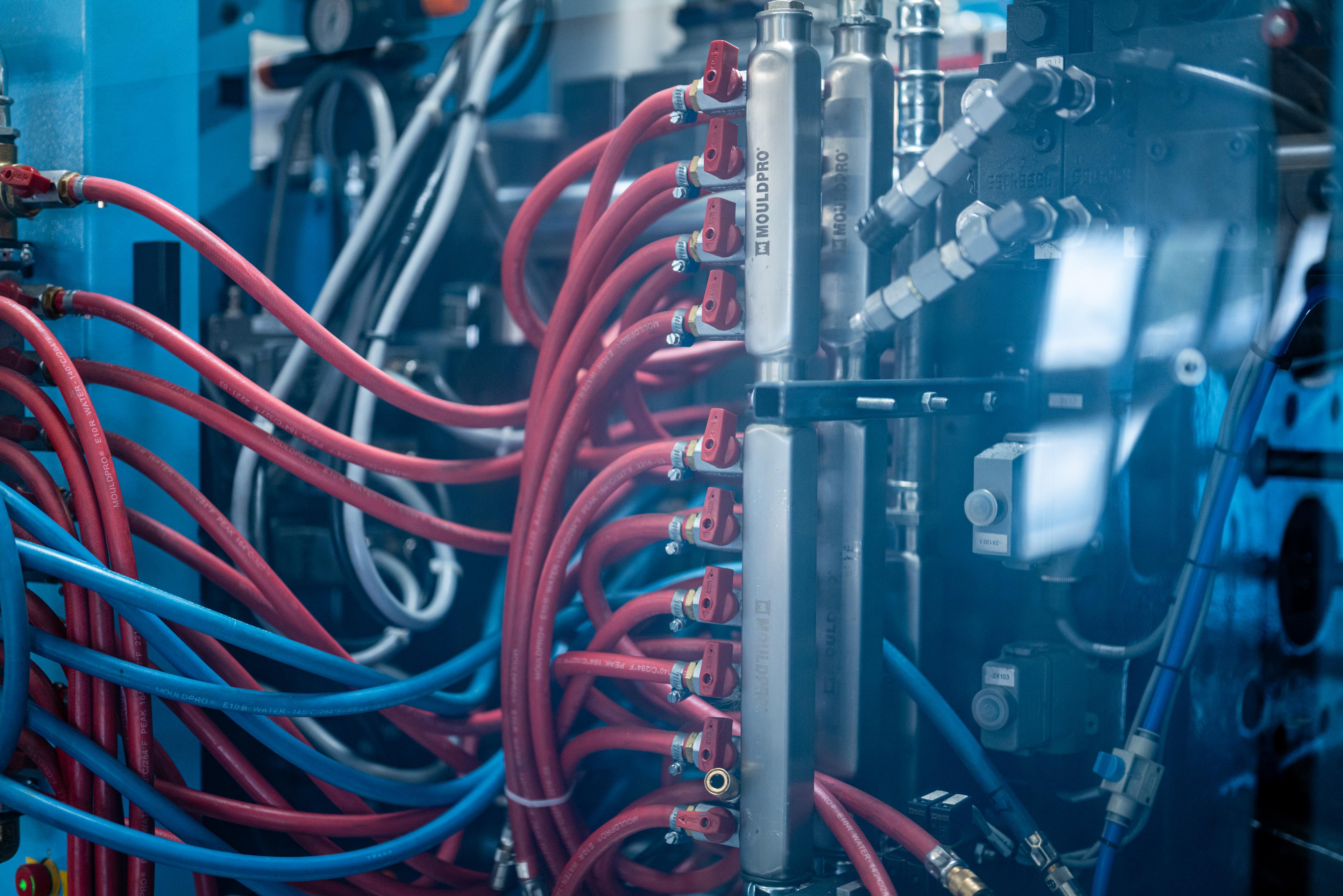

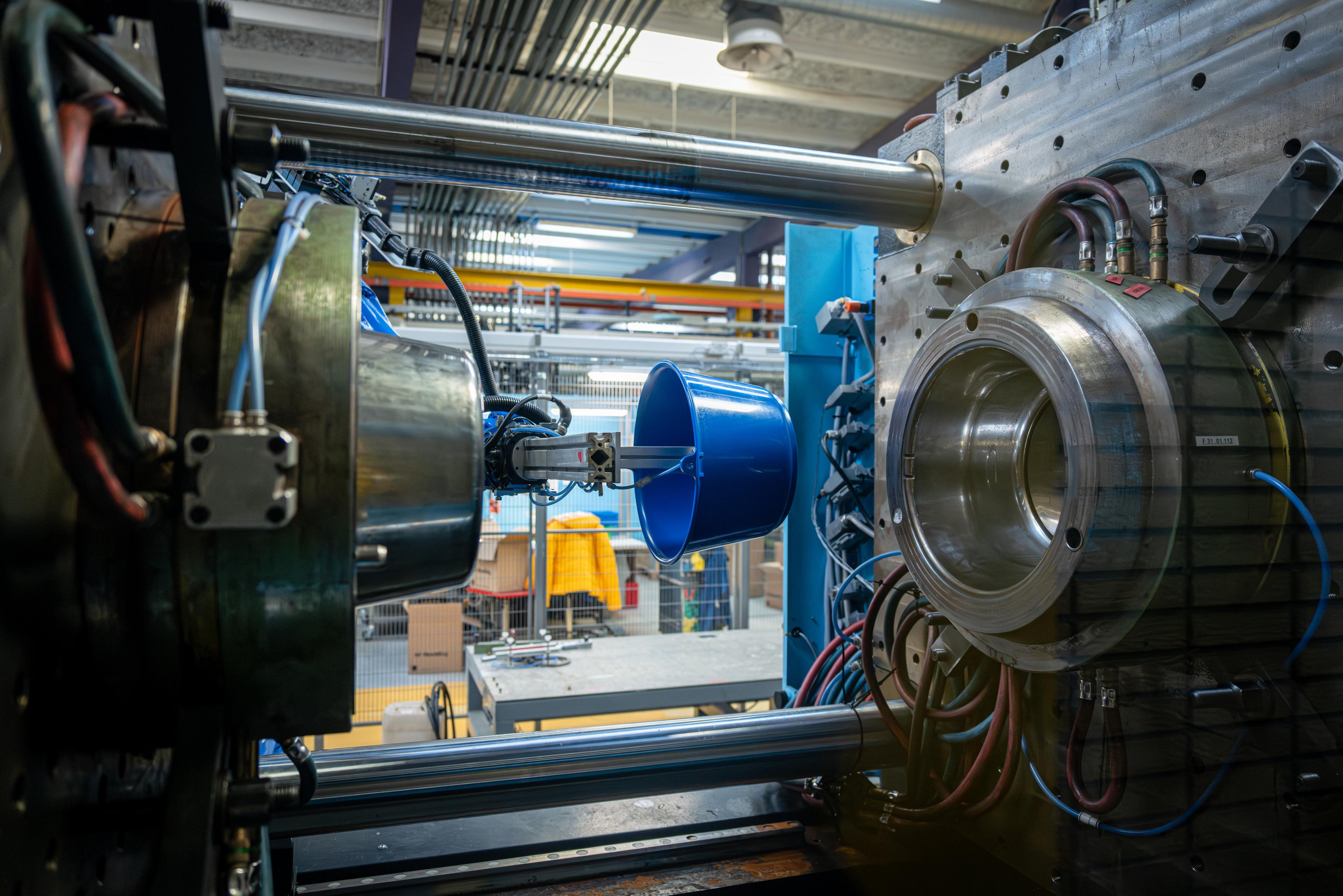

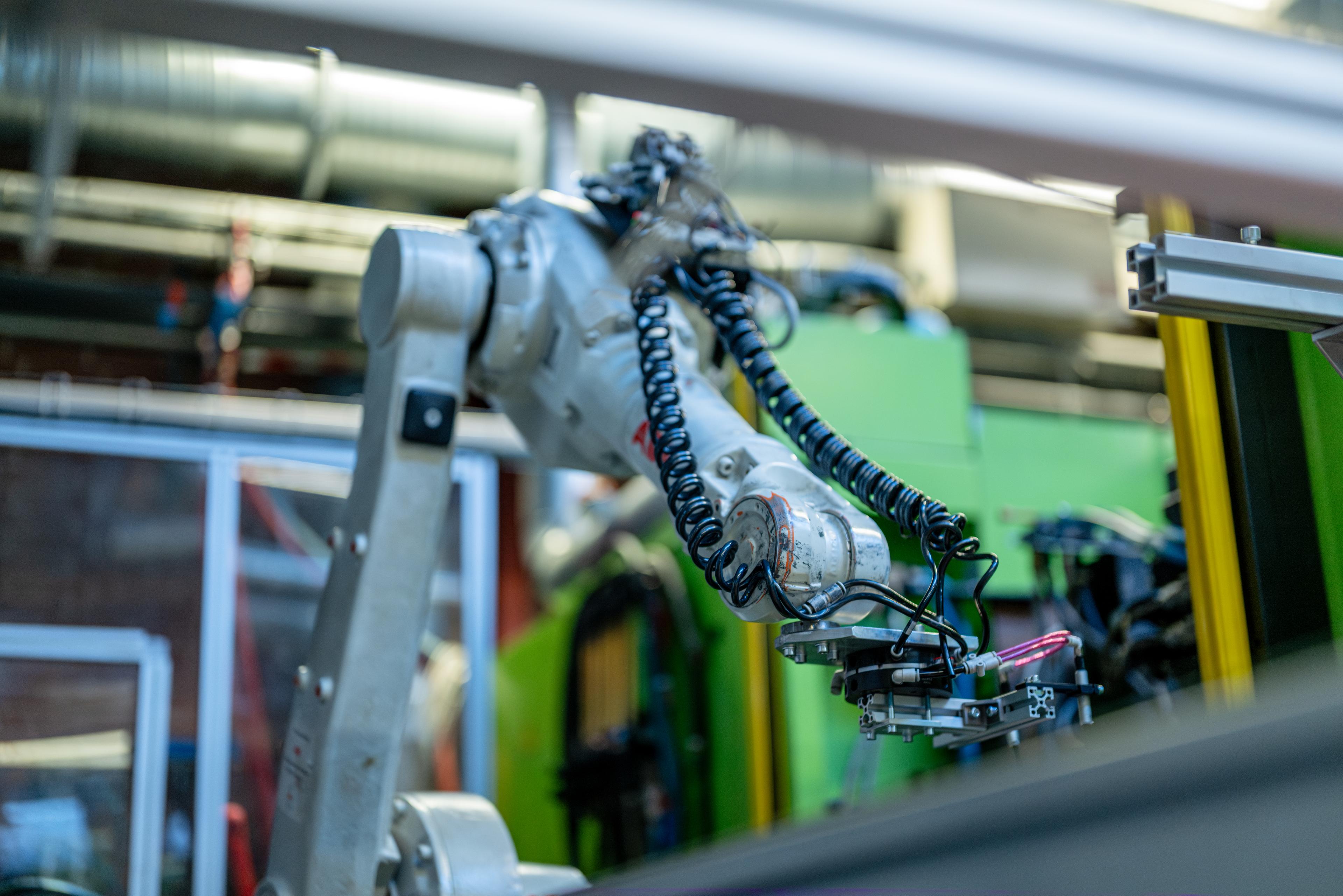

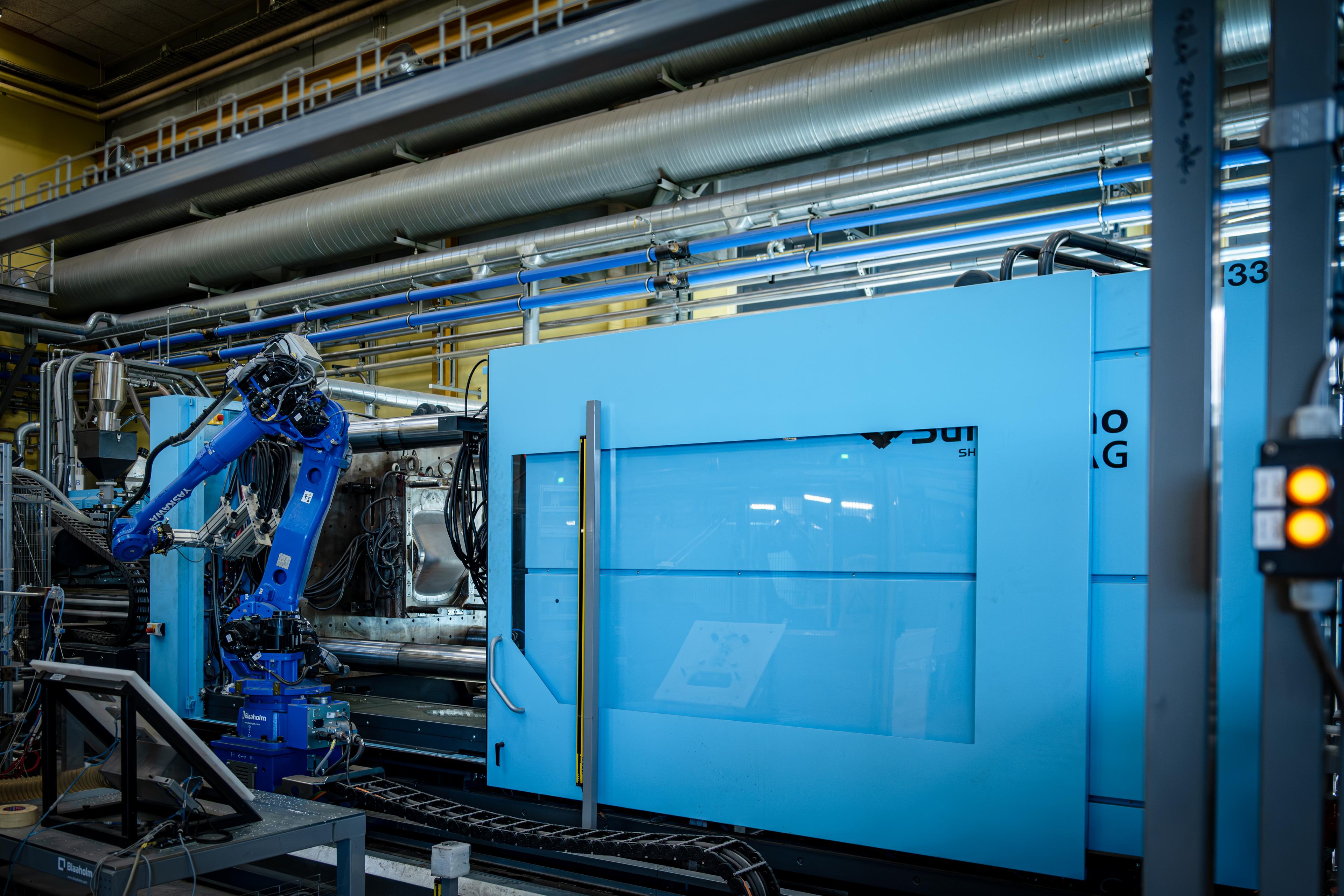

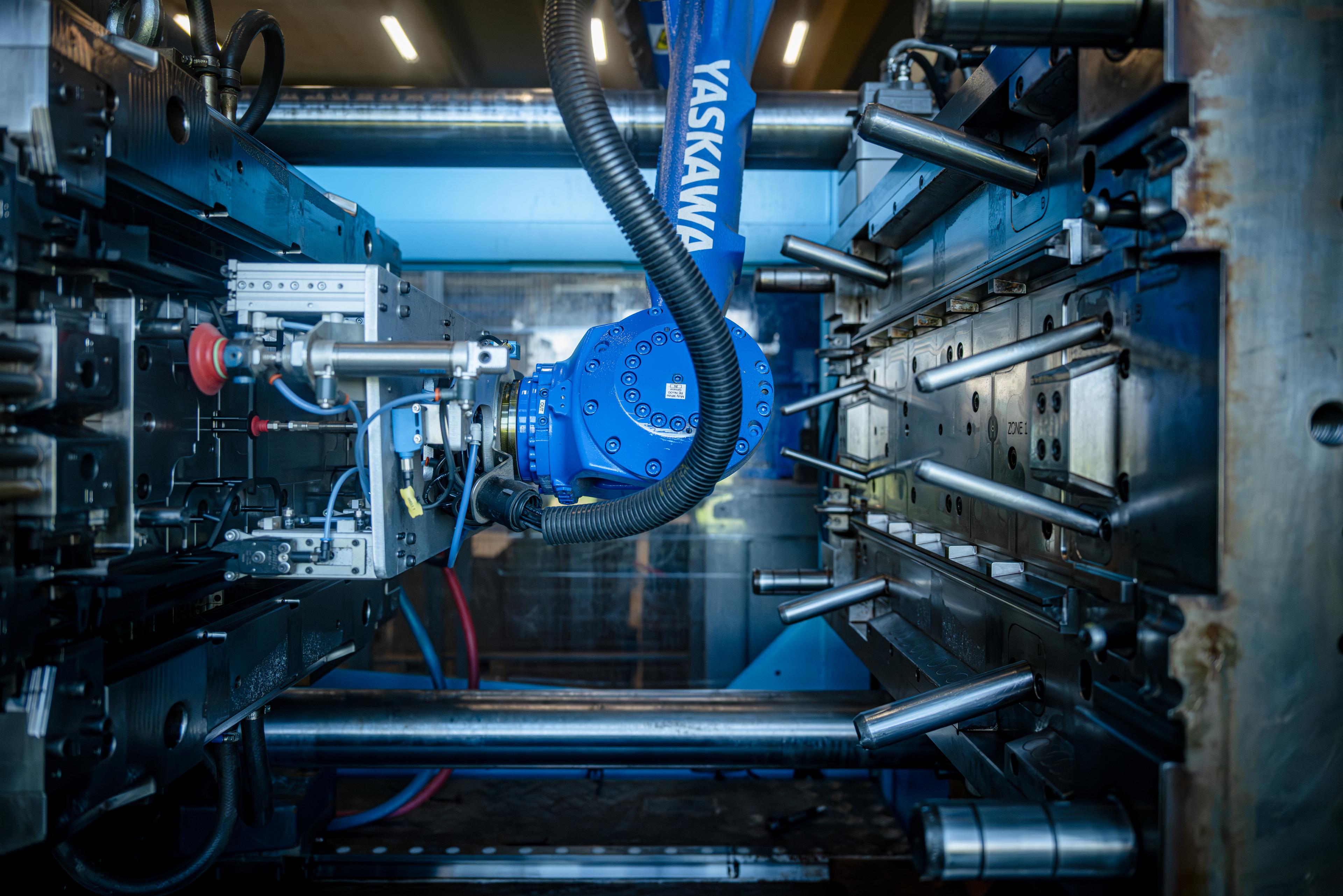

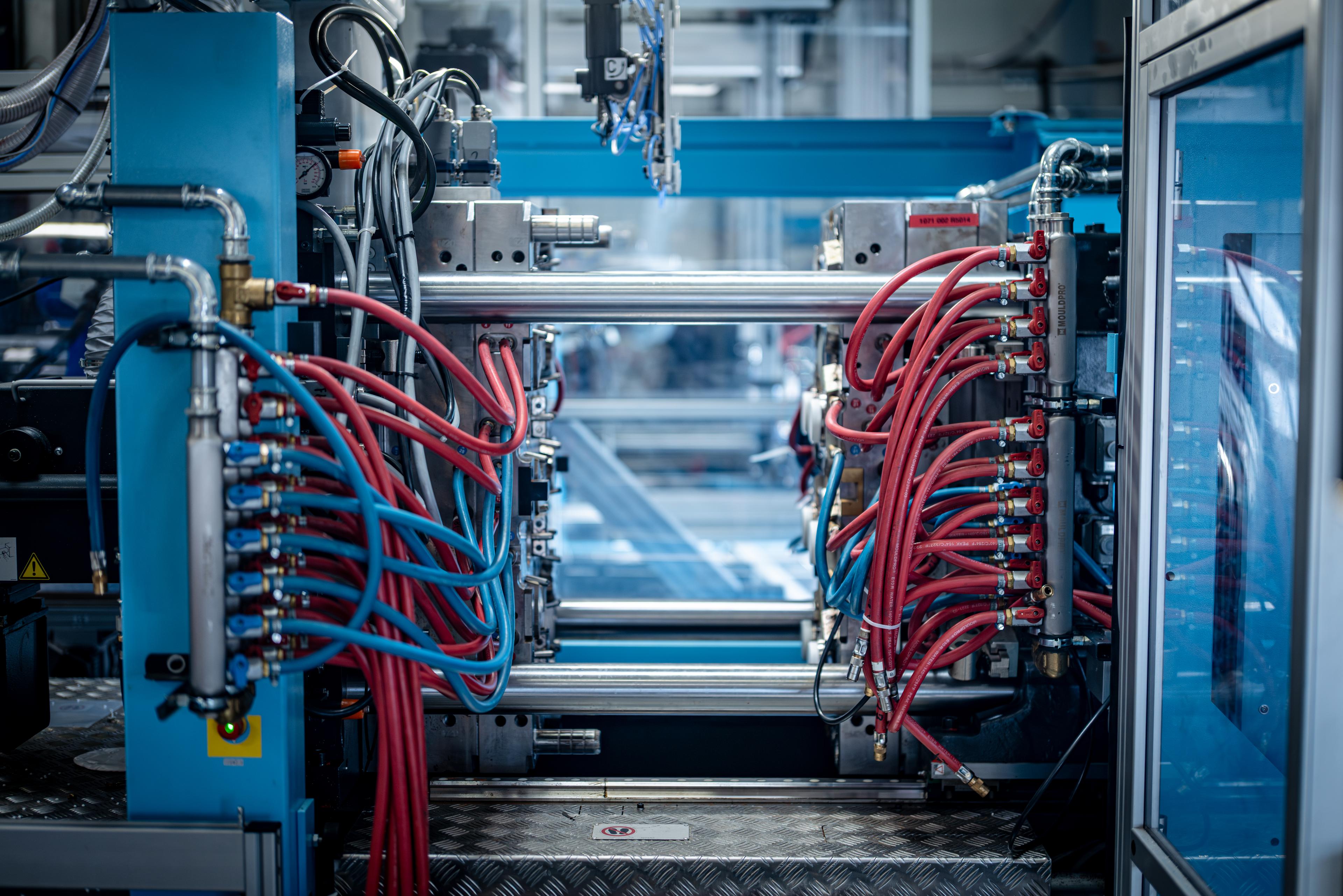

Injection Moulding

Advanced plastic injection moulding technologies and processes

Manufacturing Processes

Precision manufacturing and machining capabilities

Value-Added Services

Additional services to enhance your product and manufacturing experience

Quality & Compliance

Quality assurance, certifications, and regulatory compliance

Design & Engineering

Design optimization, engineering services, and innovation support

One-Stop Injection Moulding Shop

From concept to finished product, we handle every step. We are one of the worlds largest injection moulding companies with fast lead time.

Design & Engineering

CAD design, DFM analysis, and material selection

Rapid Prototyping

3D printing and CNC machining for quick validation

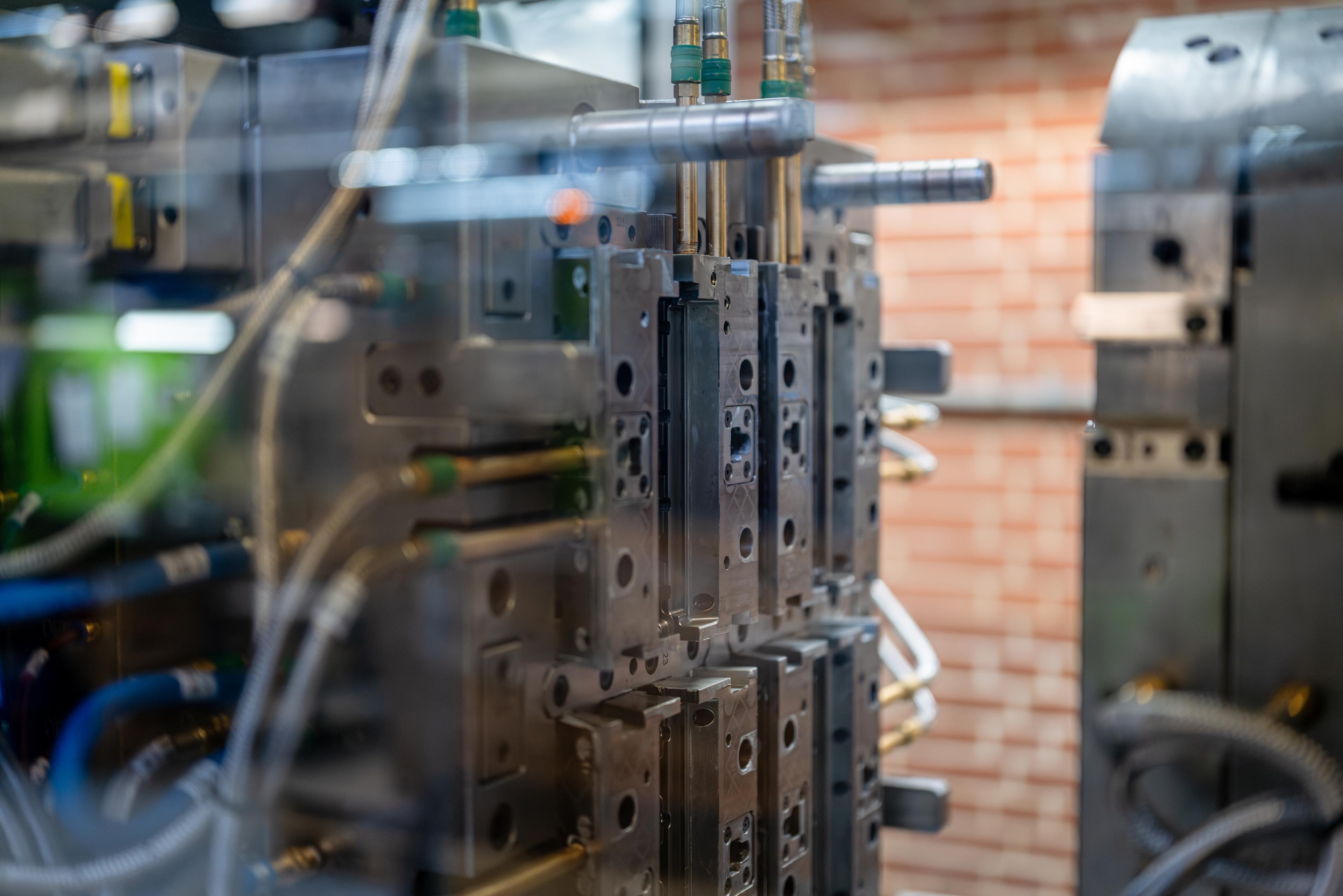

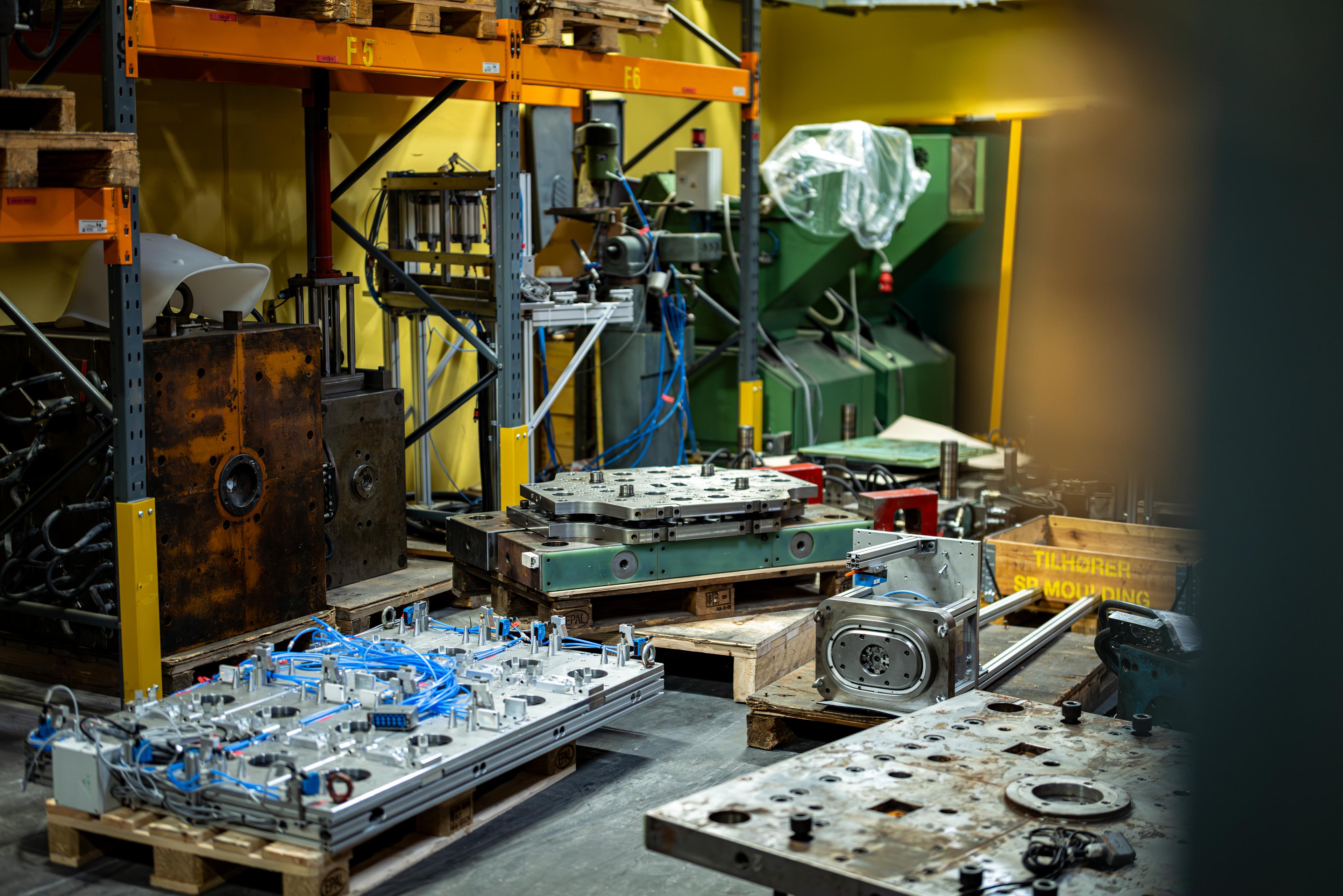

Mould Design & Tooling

Precision mould manufacturing with advanced techniques

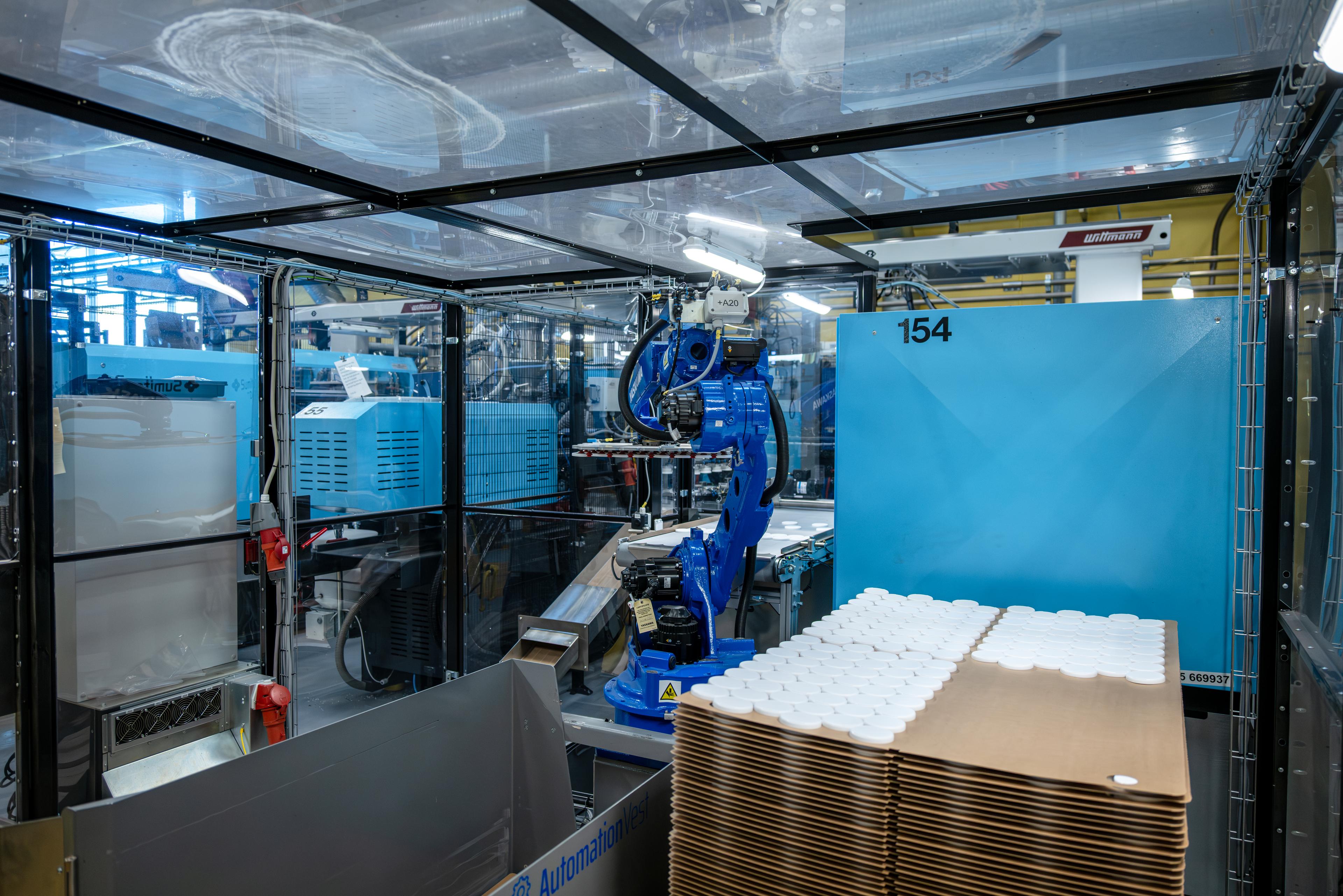

Injection Moulding

High-volume production with consistent quality

Surface Finishing

Painting, plating, and texture applications

Assembly & Packaging

Complete product assembly and custom packaging

Design & Engineering

Our experienced engineering team collaborates with you from the initial concept phase, utilizing advanced CAD software and DFM (Design for Manufacturing) analysis to optimize your product design. We ensure material selection aligns with your performance requirements, cost targets, and sustainability goals. Our engineers leverage decades of expertise to identify potential manufacturing challenges early, reducing iterations and accelerating time to market while maintaining the highest quality standards.