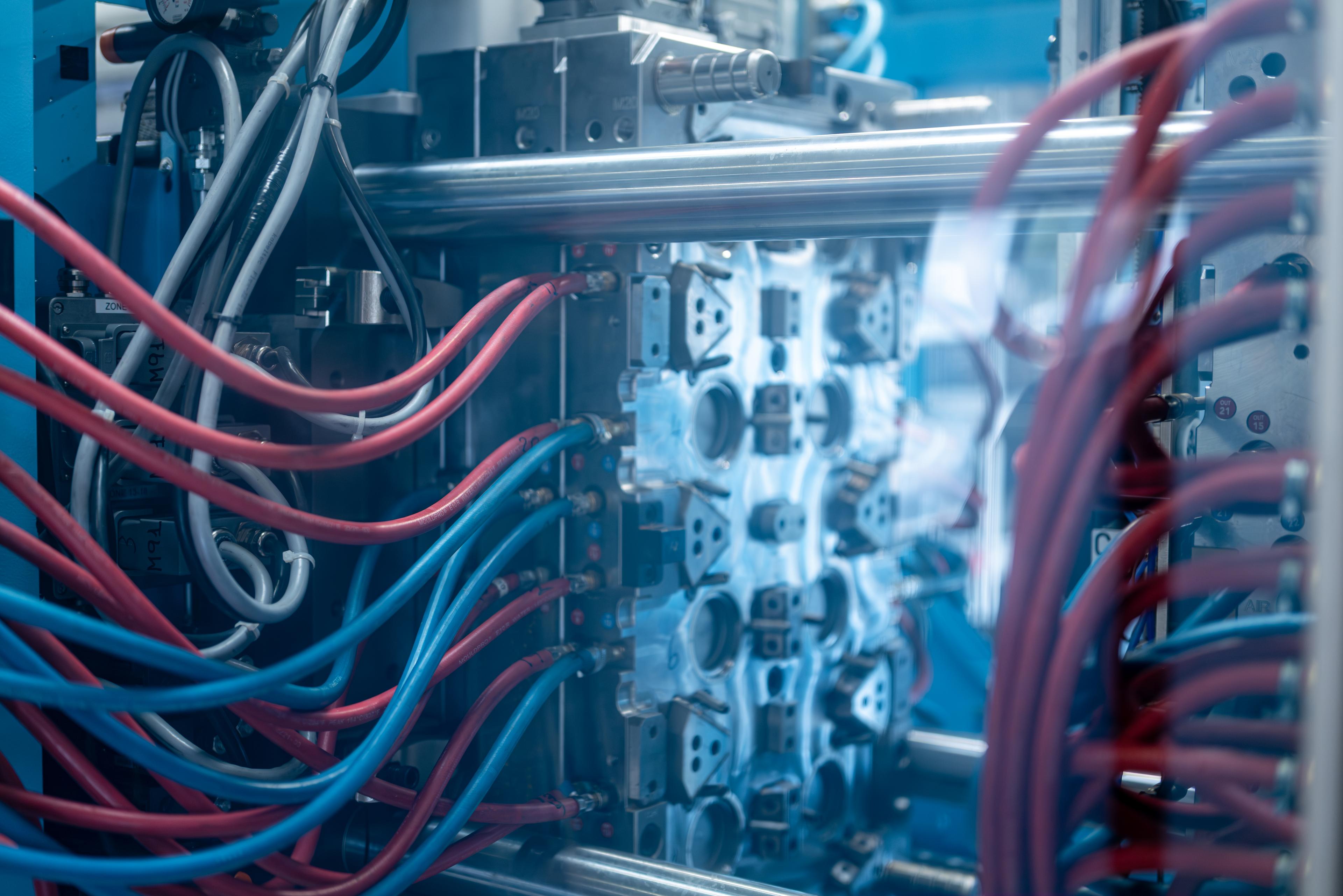

Design Engineering Services

Transform your concepts into manufacturable products with our expert design engineering team. From initial concept to production-ready designs, we optimize for manufacturability, cost, and performance.

Design Engineering Expertise

From Concept to Production

Our design engineering services bridge the gap between innovative concepts and manufacturable products. With decades of experience in plastic injection moulding and advanced manufacturing techniques, our engineers understand both the creative and practical aspects of product development. We use state-of-the-art CAD software, simulation tools, and DFM principles to ensure your designs are optimized for production success while meeting all functional requirements. Our collaborative approach involves you throughout the design process, ensuring the final product exceeds expectations.

Key Highlights

- Comprehensive DFM (Design for Manufacturing) analysis

- Advanced CAD modeling with SolidWorks and CATIA

- Moldflow simulation for injection moulding optimization

- Material selection and compatibility analysis

- Cost optimization through design refinement

- Rapid prototyping and validation support

- Tooling design and manufacturing consultation

- 24-48 hour design response times

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Measurable Value Creation

Design Engineering Benefits

Our design engineering services deliver tangible benefits that directly impact your product success and bottom line. Through systematic optimization and expert analysis, we ensure your designs are both innovative and manufacturable.

Cost Reduction

CostOptimize designs to minimize material usage, reduce manufacturing complexity, and lower production costs

Key Points:

- Material optimization strategies

- Manufacturing process simplification

- Tooling cost reduction

Faster Time to Market

SpeedAccelerate development timelines through efficient design processes and early problem identification

Key Points:

- Streamlined design iterations

- Early manufacturability validation

- Reduced prototype cycles

Enhanced Quality

QualityImprove product performance and reliability through systematic design optimization

Key Points:

- Performance optimization

- Reliability enhancement

- Defect prevention

Risk Mitigation

RiskIdentify and resolve potential issues before production to avoid costly delays and rework

Key Points:

- Early problem identification

- Manufacturing risk assessment

- Quality assurance planning

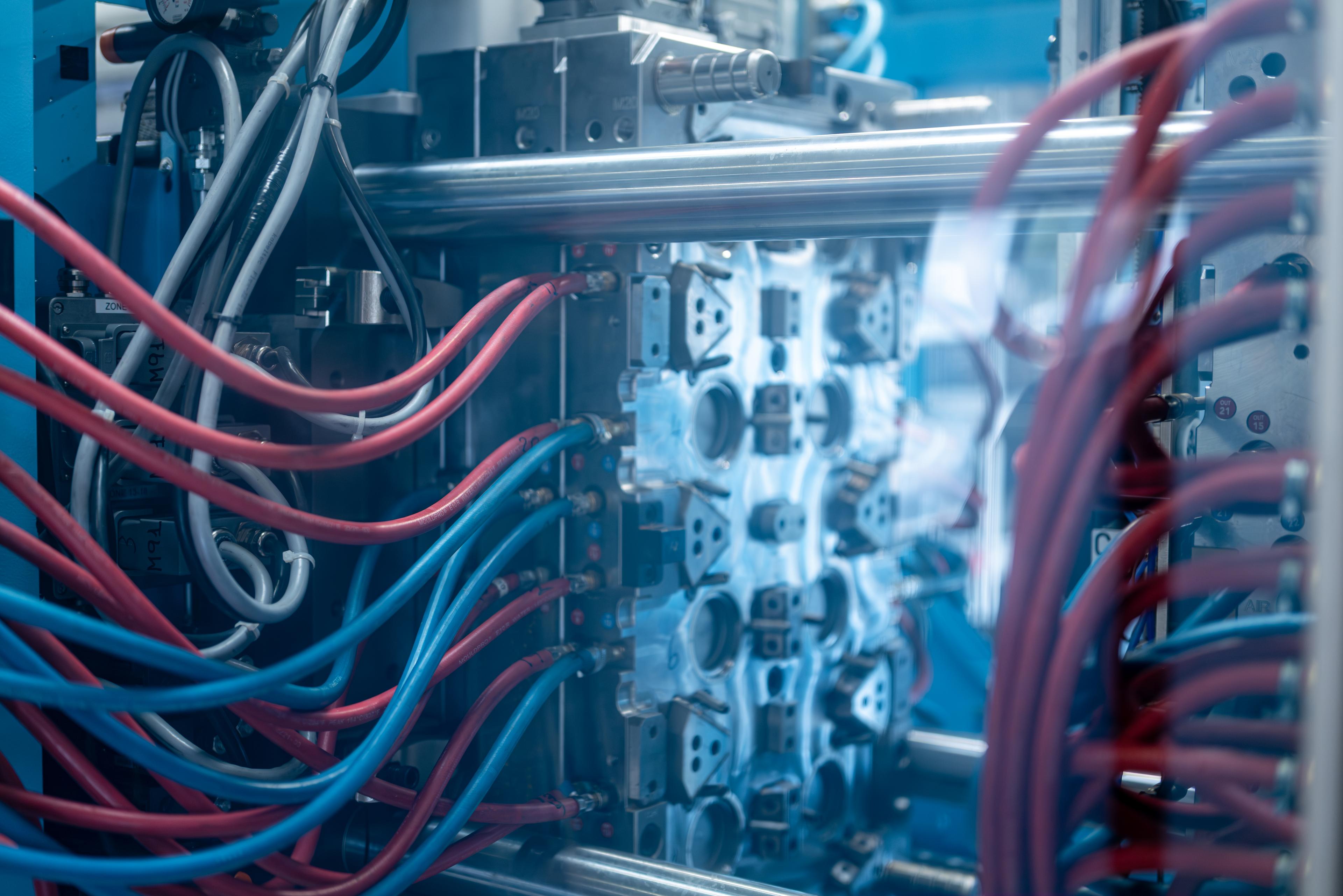

Technical Excellence in Design

Design Capabilities

Our design engineering capabilities are backed by advanced software tools, proven methodologies, and extensive experience across diverse industries and applications.

| Property | Value | Tolerance | Description |

|---|---|---|---|

CAD Software(License) SoftwareLatest version | SolidWorks Pro | Professional 3D CAD modeling platform | |

Secondary CAD(License) SoftwareIndustry standard | CATIA V5/V6 | Advanced automotive and aerospace CAD | |

Simulation(Analysis) SimulationProduction validated | Moldflow | Injection moulding simulation and optimization | |

Design Review(hours) ServiceStandard complexity | 24-48 | Typical design review delivery time | |

Model Complexity(features) CapabilityOptimized workflow | 10000+ | Maximum model complexity handling | |

Assembly Size(components) CapabilityStructured approach | 1000+ | Large assembly management capability |

Design for Manufacturing Guidelines

Best Practices for Optimal Results

Follow these proven design guidelines to ensure your parts are optimized for injection moulding and manufacturing success. Our recommendations are based on decades of experience and thousands of successful projects.

Optimal Wall Thickness Design

Maintain consistent wall thickness to prevent defects and ensure uniform material flow

Key Tips:

- Keep walls between 0.5-4.0mm for most plastics

- Maintain uniform thickness throughout the part

- Use ribs for structural reinforcement instead of thick sections

- Transition gradually between different thicknesses

Proper Draft Implementation

Include appropriate draft angles to facilitate part ejection and reduce tool wear

Key Tips:

- Apply minimum 0.5° draft to all vertical surfaces

- Increase draft for textured or deep surfaces

- Consider part geometry and ejection direction

- Use consistent draft direction throughout

Structural Reinforcement Design

Design ribs and gussets for optimal strength without causing manufacturing issues

Key Tips:

- Rib thickness should be 50-60% of wall thickness

- Provide adequate draft on rib sides

- Round all rib intersections with generous radii

- Avoid ribs that are too tall or thin

Complex Feature Management

Minimize undercuts and complex features to reduce tooling costs and complexity

Key Tips:

- Design for straight pull whenever possible

- Use side actions sparingly and strategically

- Consider snap-fit alternatives to undercuts

- Evaluate cost vs. functionality trade-offs

Need Design Consultation?

Our design engineers can review your parts and provide recommendations for optimal manufacturability and cost reduction.