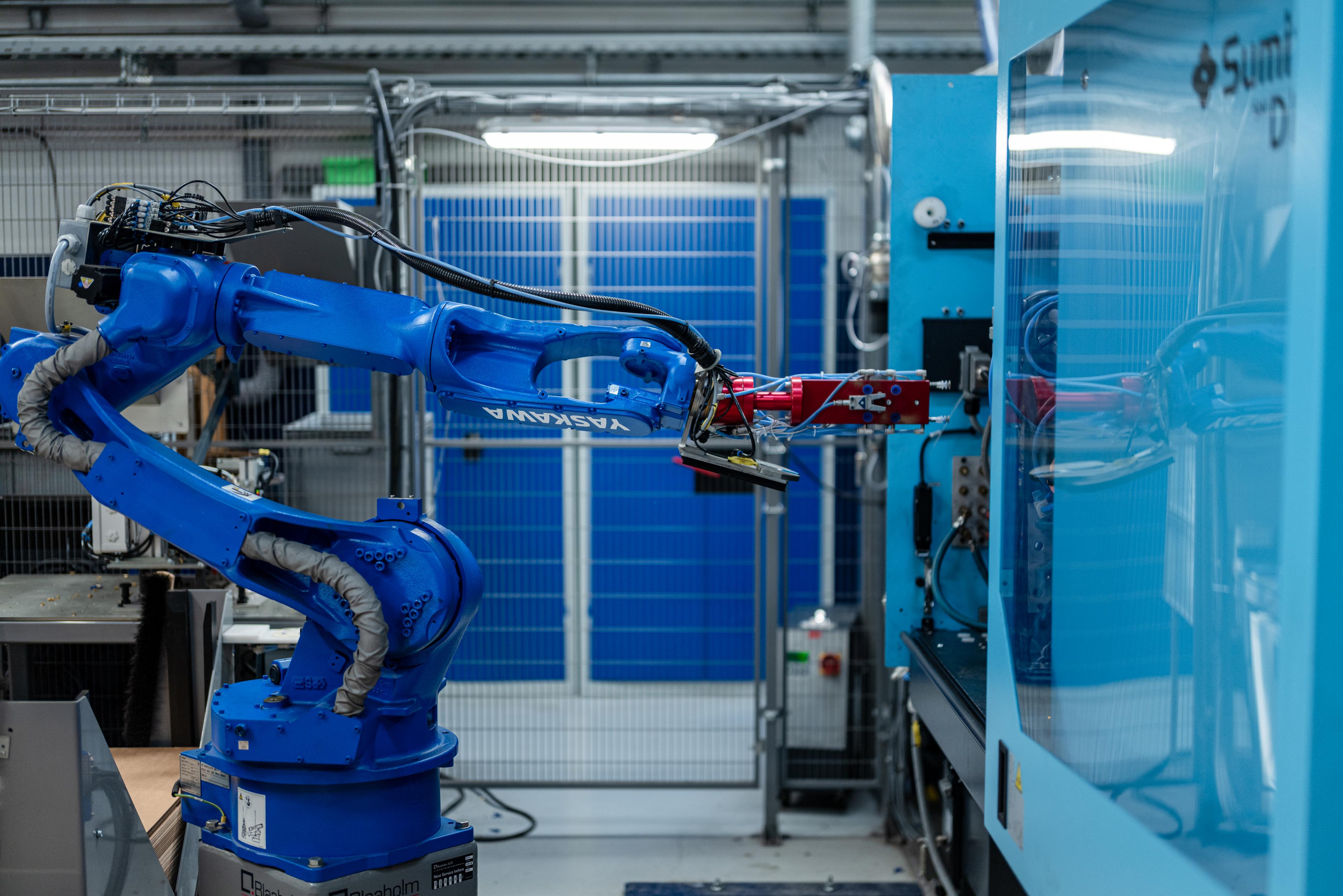

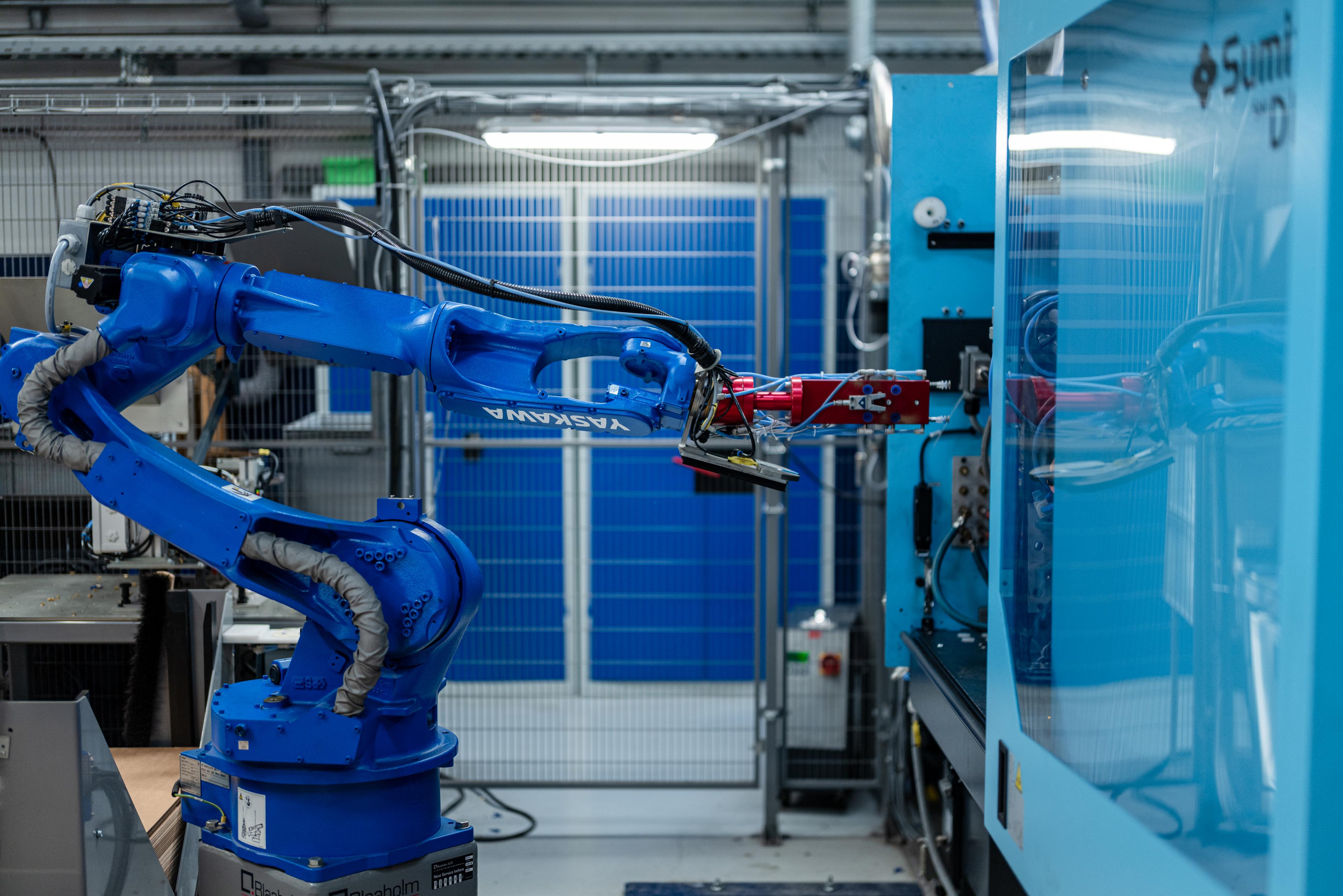

Cleanroom Injection Moulding Services

Contamination-free manufacturing in Class 7 & 8 cleanroom environments. Specialized for medical devices, pharmaceutical applications, and precision components requiring the highest cleanliness standards.

Medical-Grade Cleanroom Manufacturing

Contamination-Free Injection Moulding Excellence

Our Class 7 & 8 cleanroom injection moulding facility represents the highest standard in contamination-free manufacturing. Specifically designed for medical devices, pharmaceutical components, and precision electronics, our cleanroom environment maintains strict particle counts, bioburden control, and environmental conditions. With comprehensive validation, full traceability, and regulatory compliance, we deliver medical-grade components that meet the most stringent cleanliness and quality requirements.

Key Highlights

- ISO 14644 Class 7 & 8 certified cleanroom facility

- Advanced contamination control systems

- Medical-grade material handling and processing

- Complete environmental monitoring and validation

- Full batch traceability and documentation

- Regulatory compliance (FDA, ISO 13485, MDR)

- Biocompatible and medical-grade materials

- Expert cleanroom manufacturing team

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Medical-Grade Production Benefits

Cleanroom Manufacturing Advantages

Cleanroom injection moulding provides unparalleled contamination control and quality assurance for critical applications. Our controlled environment ensures consistent cleanliness levels, reduced contamination risk, and compliance with strict regulatory requirements for medical and pharmaceutical applications.

- Contamination Control

- Class 7/8

Strict particle count control and environmental monitoring for contamination-free manufacturing.

- Bioburden Management

- <100 CFU

Low bioburden levels with comprehensive microbial monitoring and control.

- Traceability

- 100%

Complete batch traceability from raw materials through finished components.

- Regulatory Compliance

- Full

Complete compliance with FDA, ISO 13485, MDR, and other medical regulations.

- Material Purity

- Medical Grade

Biocompatible materials with certificates of analysis and USP Class VI validation.

- Environmental Control

- Validated

Continuous monitoring of temperature, humidity, air pressure, and particle counts.

Medical-Grade Production Advantages

Cleanroom Manufacturing Benefits

Cleanroom injection moulding delivers critical benefits for medical and pharmaceutical applications, ensuring contamination-free production, regulatory compliance, and patient safety through controlled manufacturing environments and comprehensive quality systems.

Contamination Elimination

SafetyComplete elimination of particulate and microbial contamination risks.

Key Points:

- Class 7 & 8 particle count control

- Bioburden monitoring and control

- HEPA filtration systems

- Validated cleaning procedures

Regulatory Compliance

ComplianceFull compliance with medical device and pharmaceutical regulations.

Key Points:

- FDA registered facility

- ISO 13485 quality system

- MDR compliance ready

- Validated manufacturing processes

Complete Traceability

QualityFull batch traceability from raw materials to finished components.

Key Points:

- Material lot tracking

- Process parameter recording

- Environmental monitoring data

- Complete documentation packages

Patient Safety

SafetyUltimate patient safety through contamination-free, biocompatible components.

Key Points:

- Biocompatible material validation

- Sterility assurance

- Contamination risk elimination

- Quality system compliance

Quality Assurance

QualityComprehensive quality systems ensuring consistent, validated production.

Key Points:

- Statistical process control

- Environmental monitoring

- Validated test methods

- Continuous improvement programs

Regulatory Support

SupportExpert regulatory support for device approvals and market access.

Key Points:

- FDA submission support

- Technical documentation

- Regulatory compliance guidance

- Audit readiness

Medical-Grade Manufacturing Capabilities

Cleanroom Technical Specifications

Our cleanroom injection moulding capabilities meet the most stringent requirements for medical device and pharmaceutical manufacturing, with validated processes, comprehensive monitoring, and full regulatory compliance.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Cleanroom Class(classification) EnvironmentOperational state | ISO 7 & 8 | Certified cleanroom classification per ISO 14644 standards | |

Particle Count (0.5µm)(particles/ft³) Contamination ControlContinuous monitoring | <10,000 | Maximum allowable particle count for Class 8 areas | |

Bioburden Level(CFU/plate) Microbial ControlRegular testing | <100 | Maximum colony forming units per settle plate | |

Temperature Control(°C ± 2) EnvironmentalContinuous monitoring | 20-22 | Controlled temperature range for process stability | |

Humidity Control(% RH ± 5) EnvironmentalContinuous monitoring | 45-55 | Controlled humidity range for material stability | |

Air Changes(ACH) VentilationValidated system | 15-25 | Air changes per hour for contamination control |

Cleanroom Design Guidelines

Medical Device Design Excellence

Successful cleanroom injection moulding requires design optimization for medical device applications, considering biocompatibility, sterilization compatibility, and regulatory requirements while ensuring optimal manufacturability in controlled environments.

Biocompatibility Considerations

Design for biocompatibility and patient safety in medical applications.

Key Tips:

- Select biocompatible materials (USP Class VI)

- Minimize surface area for biological evaluation

- Consider patient contact duration and type

- Design for sterilization compatibility

- Avoid sharp edges or potential injury points

Clean Design Principles

Design parts to minimize contamination risks and facilitate cleaning.

Key Tips:

- Eliminate dead spaces and crevices

- Use smooth, cleanable surfaces

- Minimize particle generation potential

- Design for single-use where appropriate

- Consider packaging and sterile presentation

Medical-Grade Materials

Choose appropriate materials for medical device applications.

Key Tips:

- Verify biocompatibility certification

- Consider sterilization method compatibility

- Evaluate chemical resistance requirements

- Check extractables and leachables data

- Ensure regulatory compliance documentation

Design for Approval

Design considering regulatory requirements and approval pathways.

Key Tips:

- Follow applicable medical device standards

- Consider predicate device comparisons

- Plan for design controls documentation

- Include risk management considerations

- Prepare for regulatory submission requirements

Need Design Consultation?

Our design engineers can review your parts and provide recommendations for optimal manufacturability and cost reduction.