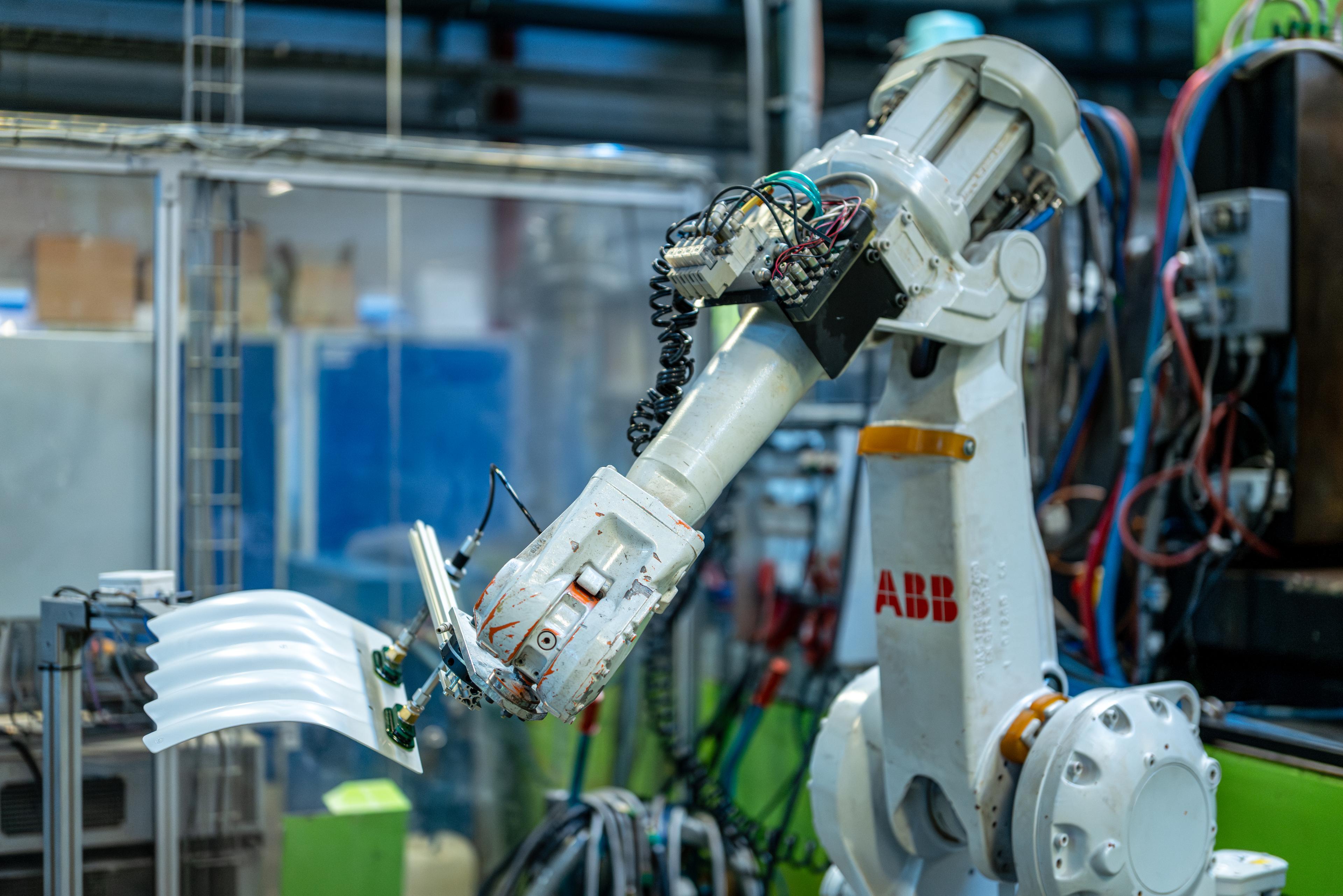

Blow Moulding Services

Lightweight, cost-effective hollow plastic components from bottles to large containers. Advanced blow moulding technology for superior strength-to-weight ratios and complex geometries.

Advanced Blow Moulding Technology

Hollow Plastic Component Excellence

Blow moulding is the optimal manufacturing process for creating hollow plastic components with superior strength-to-weight ratios and cost-effectiveness. Our advanced blow moulding capabilities encompass extrusion blow moulding, injection blow moulding, and stretch blow moulding technologies to meet diverse application requirements. From small precision bottles to large industrial containers, we deliver lightweight, durable solutions that reduce material usage while maintaining structural integrity and performance.

Key Highlights

- Advanced extrusion and injection blow moulding

- Wide range of materials and sizes

- Lightweight, cost-effective solutions

- Excellent strength-to-weight ratios

- Complex geometry capabilities

- High-volume production efficiency

- Precise wall thickness control

- Expert design and engineering support

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Hollow Component Benefits

Blow Moulding Advantages

Blow moulding offers unique advantages for creating hollow components, delivering exceptional strength-to-weight ratios, cost-effectiveness, and design flexibility. This manufacturing process enables the production of complex shapes and large volumes while minimizing material usage and weight.

- Weight Reduction

- 60-80%

Significant weight savings compared to solid alternatives while maintaining strength.

- Material Efficiency

- 90%+

Optimal material utilization with minimal waste through hollow design.

- Cost Effectiveness

- 40-60% Savings

Lower material costs and efficient production for high-volume applications.

- Design Freedom

- Complex Shapes

Create intricate hollow geometries impossible with other manufacturing methods.

- Volume Range

- 10ml-200L

Wide size capability from small precision bottles to large industrial containers.

- Production Speed

- High Volume

Rapid production cycles ideal for high-volume manufacturing requirements.

Hollow Component Advantages

Blow Moulding Benefits

Blow moulding delivers exceptional benefits for hollow component manufacturing, combining weight reduction, cost efficiency, and design flexibility with high-volume production capabilities and consistent quality.

Weight Optimization

PerformanceDramatic weight reduction while maintaining structural integrity and performance.

Key Points:

- 60-80% weight reduction vs solid alternatives

- Optimal material distribution

- Maintained strength and durability

- Reduced transportation costs

Cost Efficiency

EconomicsLower material costs and efficient production for cost-effective manufacturing.

Key Points:

- Reduced material usage

- High-speed production cycles

- Lower tooling costs vs machining

- Economies of scale benefits

Design Flexibility

DesignCreate complex hollow geometries impossible with other manufacturing methods.

Key Points:

- Complex internal geometries

- Integrated features and details

- Variable wall thickness control

- Multi-layer construction options

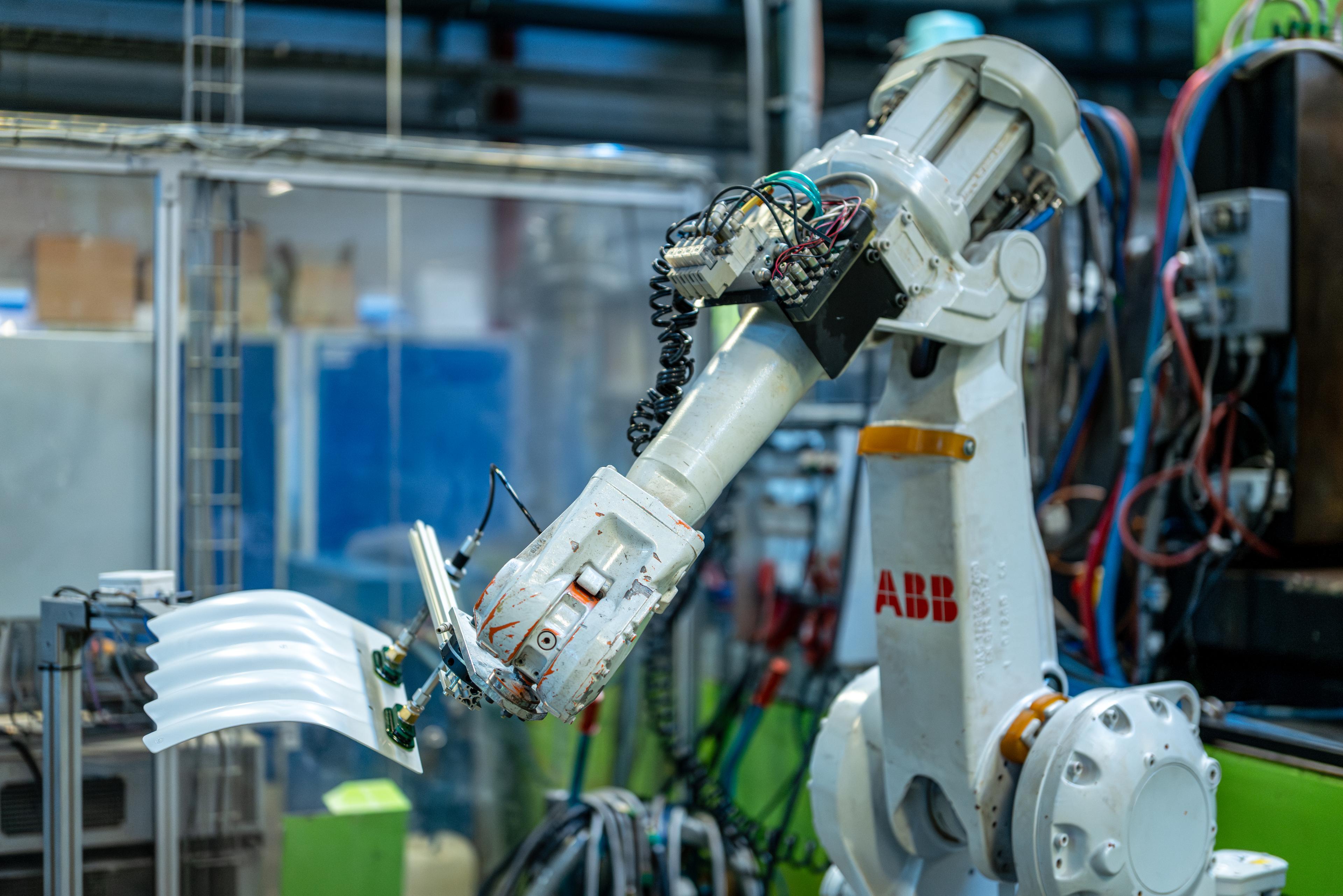

Production Efficiency

ManufacturingHigh-volume production with consistent quality and rapid cycle times.

Key Points:

- Fast production cycles

- Automated processing

- Consistent wall thickness

- High repeatability

Material Utilization

SustainabilityOptimal material efficiency with minimal waste and excellent property utilization.

Key Points:

- Minimal material waste

- Optimal strength-to-weight ratio

- Recyclable material options

- Sustainable manufacturing

Barrier Properties

ProtectionExcellent barrier performance for product protection and shelf life extension.

Key Points:

- Multi-layer barrier construction

- Gas and moisture protection

- UV resistance options

- Chemical compatibility

Manufacturing Specifications

Blow Moulding Technical Capabilities

Our blow moulding capabilities encompass multiple technologies and processes to meet diverse application requirements with consistent quality and performance across a wide range of sizes and materials.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Volume Range(capacity) CapacityVarious container sizes | 10ml-200L | Wide size capability from small bottles to large containers | |

Wall Thickness(mm) PrecisionMulti-point measurement | 0.5-10 | ±0.1mm | Precise wall thickness control across container surface |

Material Options(polymers) MaterialsVarious grades available | PE, PP, PET, PC | Wide selection of blow moulding materials | |

Production Rate(parts/hour) ProductionVaries by part complexity | 500-5000 | High-speed production depending on part size | |

Dimensional Tolerance(mm) PrecisionCritical dimensions | ±0.2 | Consistent dimensional accuracy across production | |

Neck Finish Precision(mm) PrecisionThread and sealing surfaces | ±0.05 | High precision for threaded and closure interfaces |

Blow Moulding Design Guidelines

Optimize Your Design for Blow Moulding

Successful blow moulding requires design optimization to leverage the unique advantages of hollow component manufacturing while ensuring optimal processability, performance, and cost-effectiveness.

Optimal Wall Distribution

Design appropriate wall thickness for strength, material efficiency, and process control.

Key Tips:

- Maintain uniform wall thickness where possible

- Design for parison swell and stretch ratios

- Consider blow-up ratio for optimal thickness

- Plan for material distribution during forming

- Account for thinning in stretched areas

Hollow Shape Design

Design hollow geometries for optimal strength, functionality, and manufacturability.

Key Tips:

- Avoid sharp corners and stress concentrations

- Design smooth transitions and radii

- Consider material flow during blow forming

- Plan for uniform cooling and shrinkage

- Include draft angles for easy part removal

Reinforcement and Features

Incorporate structural features for optimal performance and functionality.

Key Tips:

- Use ribs and corrugations for strength

- Design integral handles and gripping features

- Include stacking and nesting features

- Plan for closure and sealing interfaces

- Consider labeling and decoration areas

Manufacturing Optimization

Design for optimal blow moulding process performance and efficiency.

Key Tips:

- Consider parison programming requirements

- Design for uniform heating and cooling

- Plan for trimming and finishing operations

- Include quality control and inspection features

- Optimize for material usage and waste reduction

Need Design Consultation?

Our design engineers can review your parts and provide recommendations for optimal manufacturability and cost reduction.