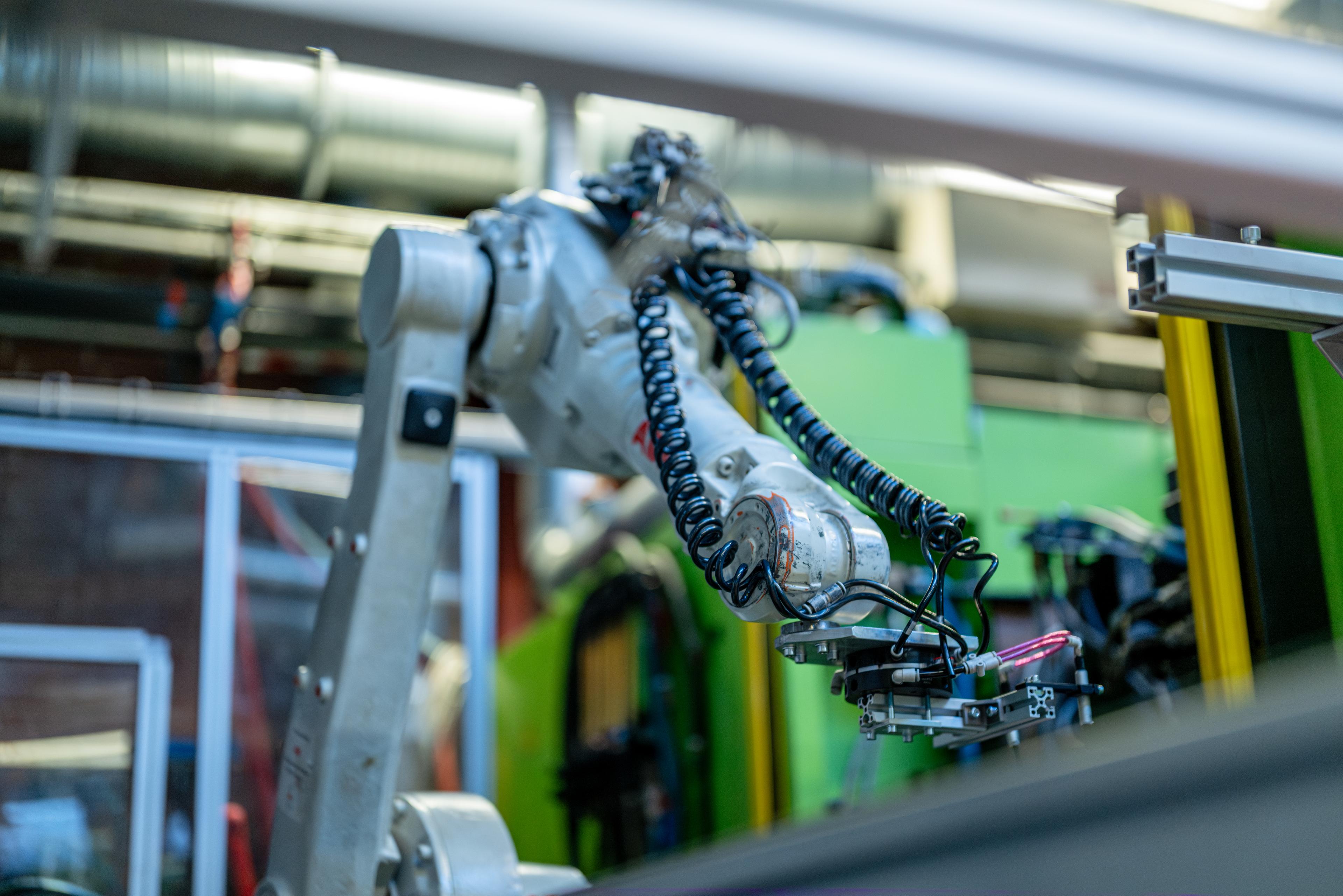

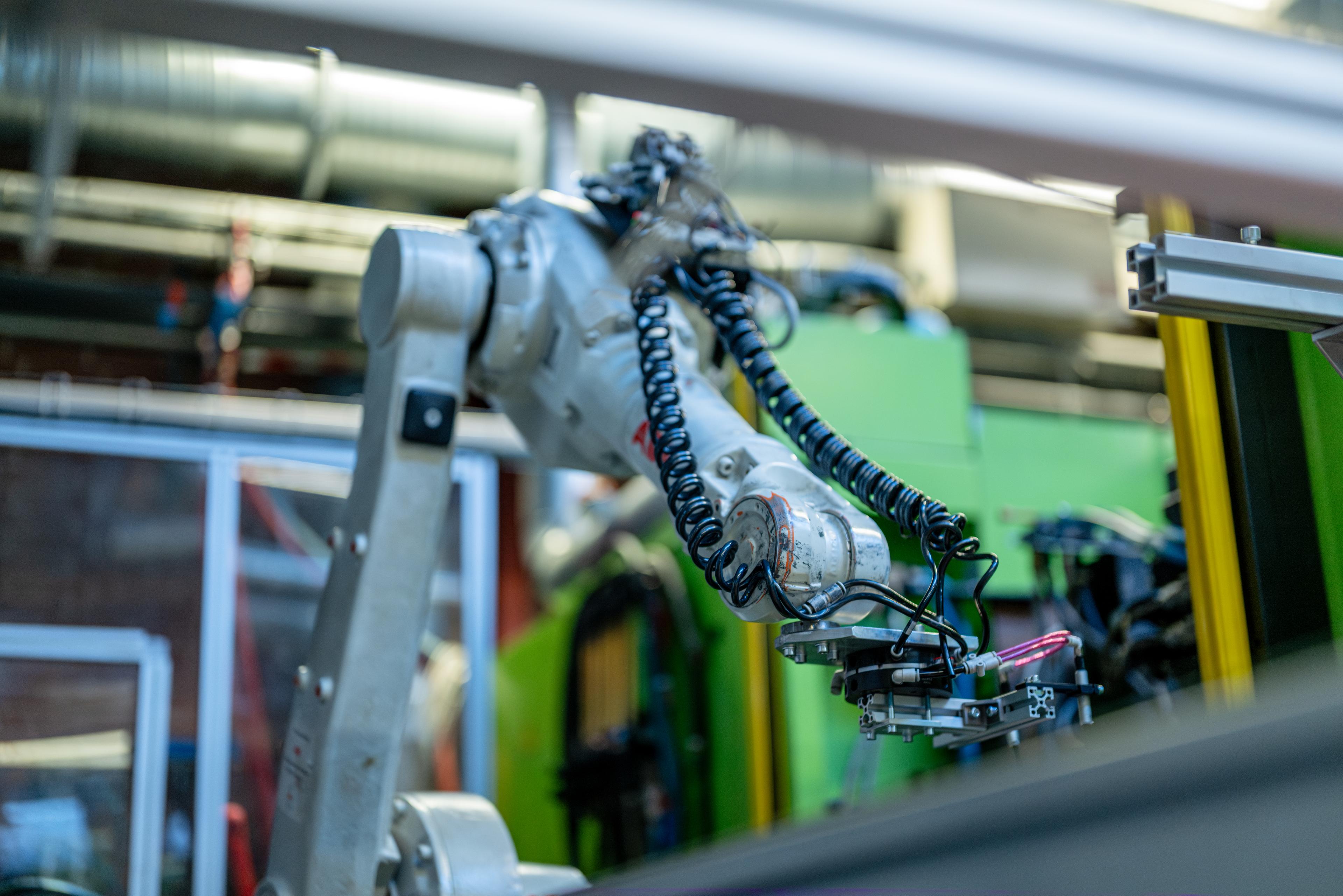

CNC Turning Services

Precision live-tool turning for shafts, bushings, and complex cylindrical components with excellent finish and concentricity.

Precision Turning

Consistent Quality

Our CNC turning services deliver precision cylindrical components with outstanding roundness, concentricity, and surface finish. Equipped with live tooling, sub-spindles, and bar feeders, our turning centers complete complex parts in a single setup, reducing lead time and ensuring repeatable quality across metals and engineering plastics.

Key Highlights

- Live-tool and Y-axis turning centers

- Bar-fed and chucker capability

- Sub-spindle for complete parts

- Precision threading and grooving

- Superior surface finish and concentricity

- Comprehensive inspection reporting

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Performance That Scales

Operational Benefits

Integrated turning, live-tool machining, and inspection deliver reliable components that meet industry-specific requirements.

Concentricity Control

QualityTight runout and concentricity for bearing, sealing, and rotating assemblies.

Key Points:

- In-process gauging at the machine

- CMM and roundness inspection reports

- SPC monitoring on critical dimensions

Lights-Out Efficiency

CapacityAutomated bar feeders and part catchers maximize unattended production time.

Key Points:

- 24/7 machining capability

- Quick-change tooling for rapid setups

- Tool wear monitoring and adaptive offsets

Material Versatility

CapabilityExperience machining aluminum, steels, stainless, titanium, brass, and plastics.

Key Points:

- Optimized feeds and speeds per material

- Certified raw material sourcing

- Surface treatment integration

Responsive Lead Times

TimeFast RFQ delivery, expedited prototypes, and agile scheduling keep programs moving.

Key Points:

- Quote responses within 24 hours

- Prototype builds in days

- Dedicated program management

Technical Insights for Engineers

Turning Capabilities

Advanced turning centers, automation, and metrology resources support demanding projects across industries.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Max Turning Diameter(mm) CapacityStandard chucking setup | 400 | Handles medium-to-large diameter components with tight tolerance requirements. | |

Max Turning Length(mm) CapacitySteady rest supported | 800 | Extended bed length supports long shafts and cylindrical parts. | |

Bar Feed Capacity(mm) ThroughputMaterial dependent | Up to 75 | Automatic bar feeders enable unattended production and rapid throughput. | |

Surface Finish(µm) FinishAs-turned to finished | Ra 0.4-1.6 | Fine surface finish achievable as-turned with optional polishing or grinding. | |

Threading Capability CapabilityPer specification | Metric / Imperial | Precision external and internal threading with gauging and certification. | |

Lead Time(days) TimeExpedite options available | 2-7 | Standard lead time for prototypes and bridge production runs. |