2K Injection Moulding Services

Eliminate assembly costs with advanced dual-material overmoulding technology. Reduce production time by 75% and assembly costs by 60%.

Advanced Dual-Material Manufacturing

2K Injection Moulding Excellence

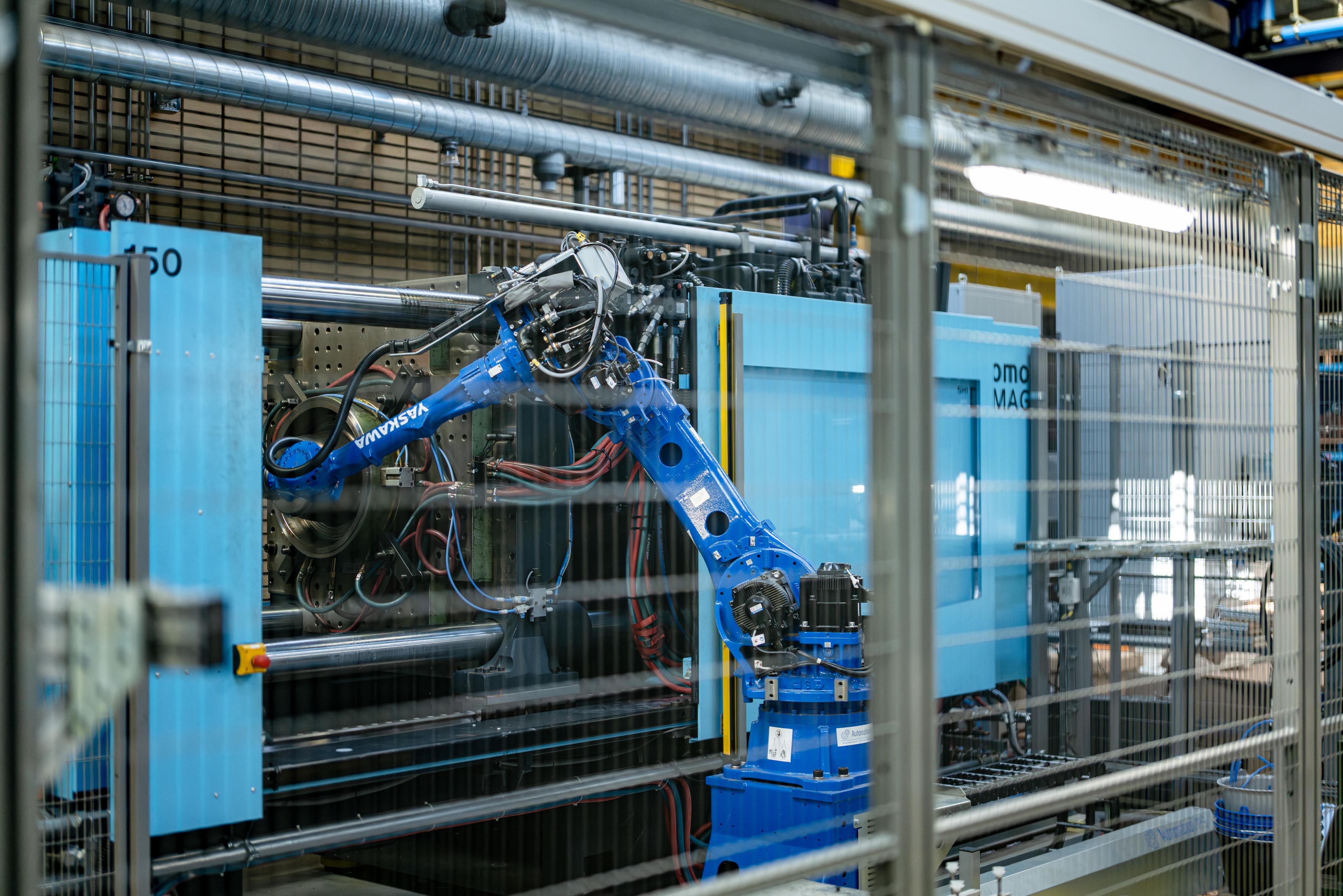

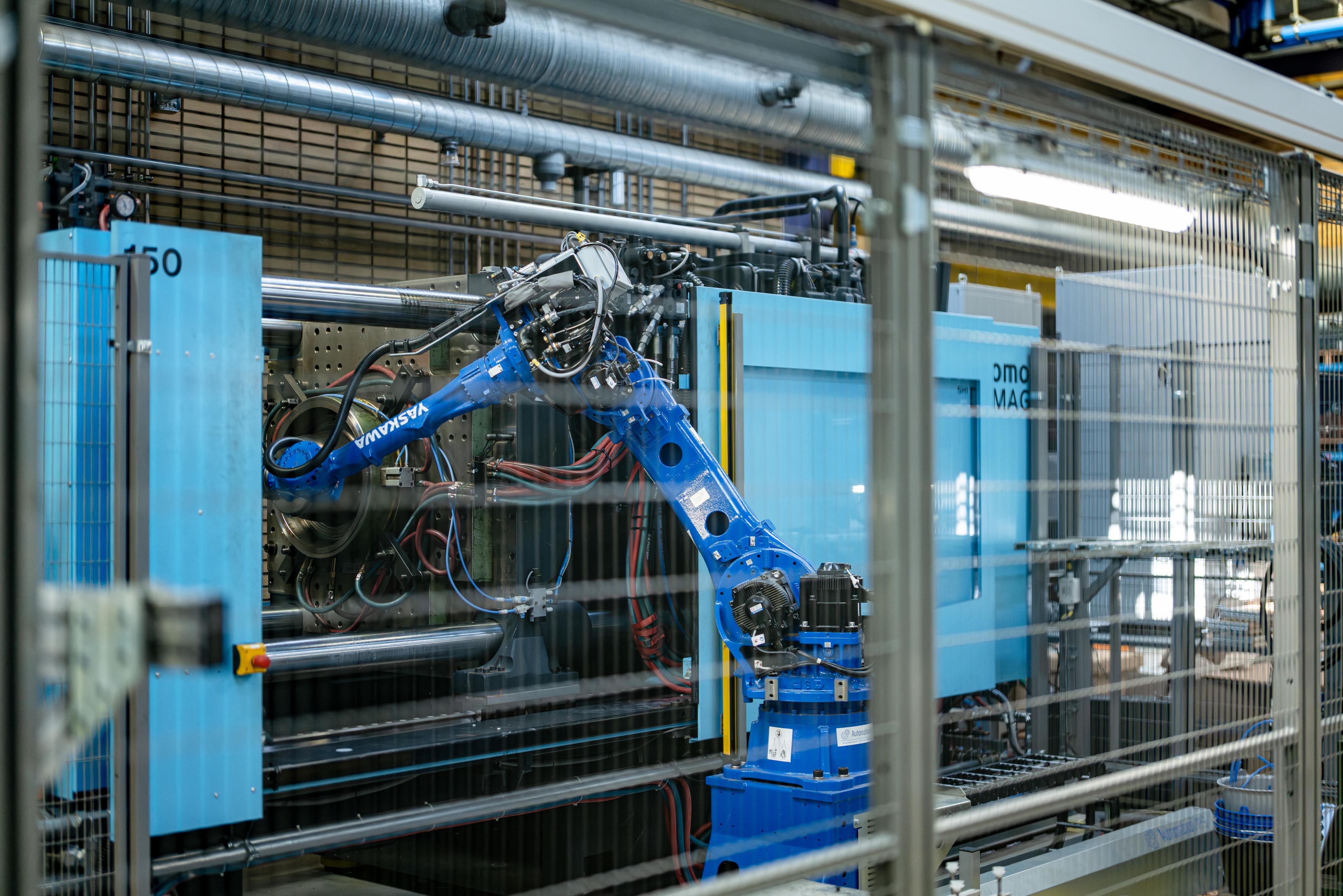

2K injection moulding represents the pinnacle of advanced manufacturing, combining two different materials in a single moulding cycle to create parts with enhanced functionality and aesthetics. Our state-of-the-art 2K technology eliminates the need for secondary assembly operations, reducing costs while improving product quality and consistency. With over 25 years of moulding expertise, we deliver complex dual-material solutions for automotive, medical, electronics, and consumer applications.

Key Highlights

- Advanced dual-material technology

- Single-shot moulding process

- Molecular-level material bonding

- Elimination of assembly operations

- Superior part quality and consistency

- Complex geometry capabilities

- Cost-effective production solutions

- Expert engineering support

Additional Capabilities

Book a free technical consultation

Speak with a manufacturing engineer within 48 hours. Get rapid DFM insights, material guidance, and a clear path to production.

Dual-Material Performance Benefits

2K Moulding Advantages

2K injection moulding delivers exceptional performance through the combination of different materials in a single moulding cycle. This advanced process creates molecular bonds between materials that are stronger than mechanical fasteners or adhesives, while enabling design possibilities impossible with traditional manufacturing methods.

- Molecular Bonding

- Permanent

Creates unbreakable bonds between different materials through chemical adhesion at the molecular level.

- Assembly Elimination

- 100%

Completely eliminates secondary assembly operations, reducing labor costs and improving quality.

- Design Freedom

- Unlimited

Enables complex geometries and material combinations impossible with traditional methods.

- Quality Consistency

- ±0.02mm

Automated process ensures consistent quality and dimensional accuracy across production runs.

- Cost Efficiency

- 60% Savings

Significant cost reduction through elimination of assembly labor and secondary operations.

- Time Reduction

- 75% Faster

Dramatically reduced production time through single-shot manufacturing process.

Measurable Manufacturing Advantages

2K Injection Moulding Benefits

2K injection moulding delivers quantifiable benefits that directly impact your manufacturing efficiency and product quality. Our proven track record demonstrates consistent value creation through reduced costs, improved functionality, and enhanced product aesthetics.

Cost Reduction

FinancialEliminate assembly labor and secondary operations through single-shot manufacturing.

Key Points:

- 60% reduction in total manufacturing costs

- Elimination of assembly labor

- Reduced inventory complexity

- Lower defect rates

Time Savings

EfficiencyDramatically reduced production time through integrated manufacturing process.

Key Points:

- 75% reduction in production time

- Single moulding cycle operation

- Eliminated assembly steps

- Faster time-to-market

Superior Quality

QualityMolecular bonding creates stronger connections than mechanical fasteners or adhesives.

Key Points:

- Molecular-level material bonding

- No delamination risk

- Consistent quality across production

- Enhanced durability

Design Innovation

InnovationEnable complex geometries and material combinations impossible with traditional methods.

Key Points:

- Unlimited design possibilities

- Complex geometry capability

- Multi-material functionality

- Enhanced product aesthetics

Process Control

ManufacturingAutomated manufacturing ensures consistent quality and repeatability.

Key Points:

- Automated process control

- Statistical process monitoring

- Consistent dimensional accuracy

- Reduced human error

Assembly Elimination

SimplificationIntegrate multiple components into a single moulded part.

Key Points:

- Zero secondary assembly required

- Integrated sealing solutions

- Reduced part count

- Simplified supply chain

Advanced Manufacturing Specifications

2K Moulding Technical Capabilities

Our 2K injection moulding capabilities are backed by state-of-the-art equipment and rigorous process controls. These specifications represent our proven performance metrics across diverse applications and industries.

| Property | Value | Tolerance | Description |

|---|---|---|---|

Shot Capacity(grams) CapacityStandard operating conditions | 2000 | ±2% | Maximum material volume per moulding cycle |

Clamping Force(tons) EquipmentVarious machine sizes | 50-1500 | Wide range of machine capacities available | |

Dimensional Tolerance(mm) PrecisionStandard tolerances | ±0.05 | Precision moulding capabilities | |

Cycle Time(seconds) PerformanceTypical production | 15-120 | Optimized for efficiency based on part complexity | |

Material Combinations(pairs) MaterialsLaboratory validation | 50+ | Validated compatible material combinations | |

Part Weight Range(grams) CapacityVarious applications | 1-2000 | From precision components to large parts |

2K Moulding Design Guidelines

Optimize Your Design for Dual-Material Success

Successful 2K moulding requires careful consideration of material compatibility, part geometry, and processing parameters. Our design guidelines, developed through decades of experience, ensure optimal results for your dual-material applications.

Compatible Material Pairing

Choose materials with compatible processing temperatures and chemical bonding properties.

Key Tips:

- Validate material compatibility through testing

- Consider shrinkage differences between materials

- Ensure processing temperature compatibility

- Evaluate chemical bonding potential

- Test long-term adhesion performance

Optimal Geometry Design

Design parts to maximize bonding area and minimize stress concentrations.

Key Tips:

- Maximize contact area between materials

- Avoid sharp transitions between materials

- Design for proper material flow

- Consider differential shrinkage effects

- Include mechanical interlocks where appropriate

Wall Thickness Considerations

Maintain appropriate wall thickness for both materials to ensure quality bonding.

Key Tips:

- Keep first shot walls 1.5-4.0mm thick

- Minimum 0.5mm thickness for second shot

- Avoid thick sections that cause sink marks

- Transition gradually between thicknesses

- Consider cooling and cycle time implications

Bonding Surface Optimization

Design bonding surfaces to maximize molecular adhesion between materials.

Key Tips:

- Create maximum surface area for bonding

- Avoid contamination of bonding surfaces

- Design for proper material encapsulation

- Include undercuts for mechanical bonding

- Consider surface texture for adhesion

Need Design Consultation?

Our design engineers can review your parts and provide recommendations for optimal manufacturability and cost reduction.